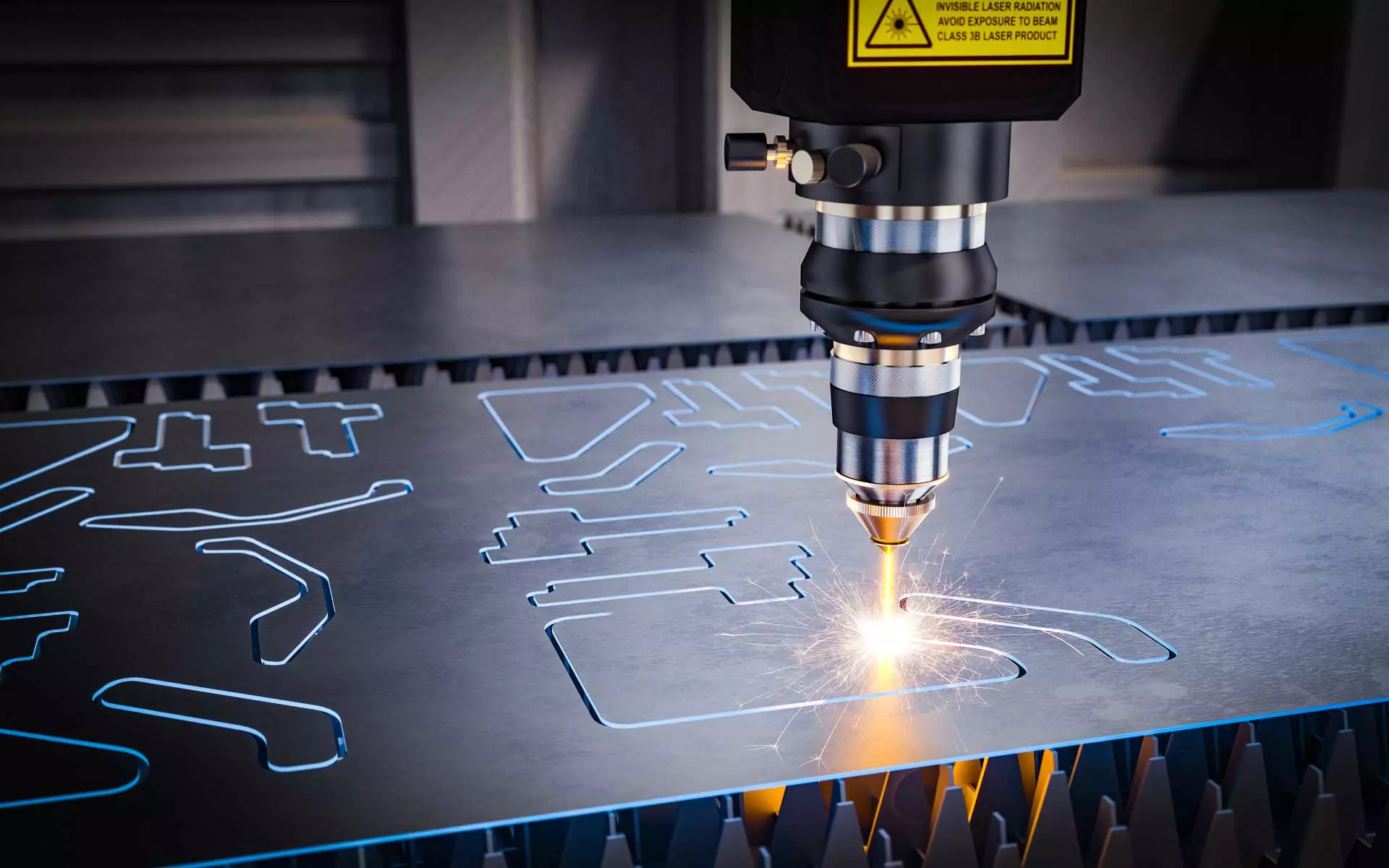

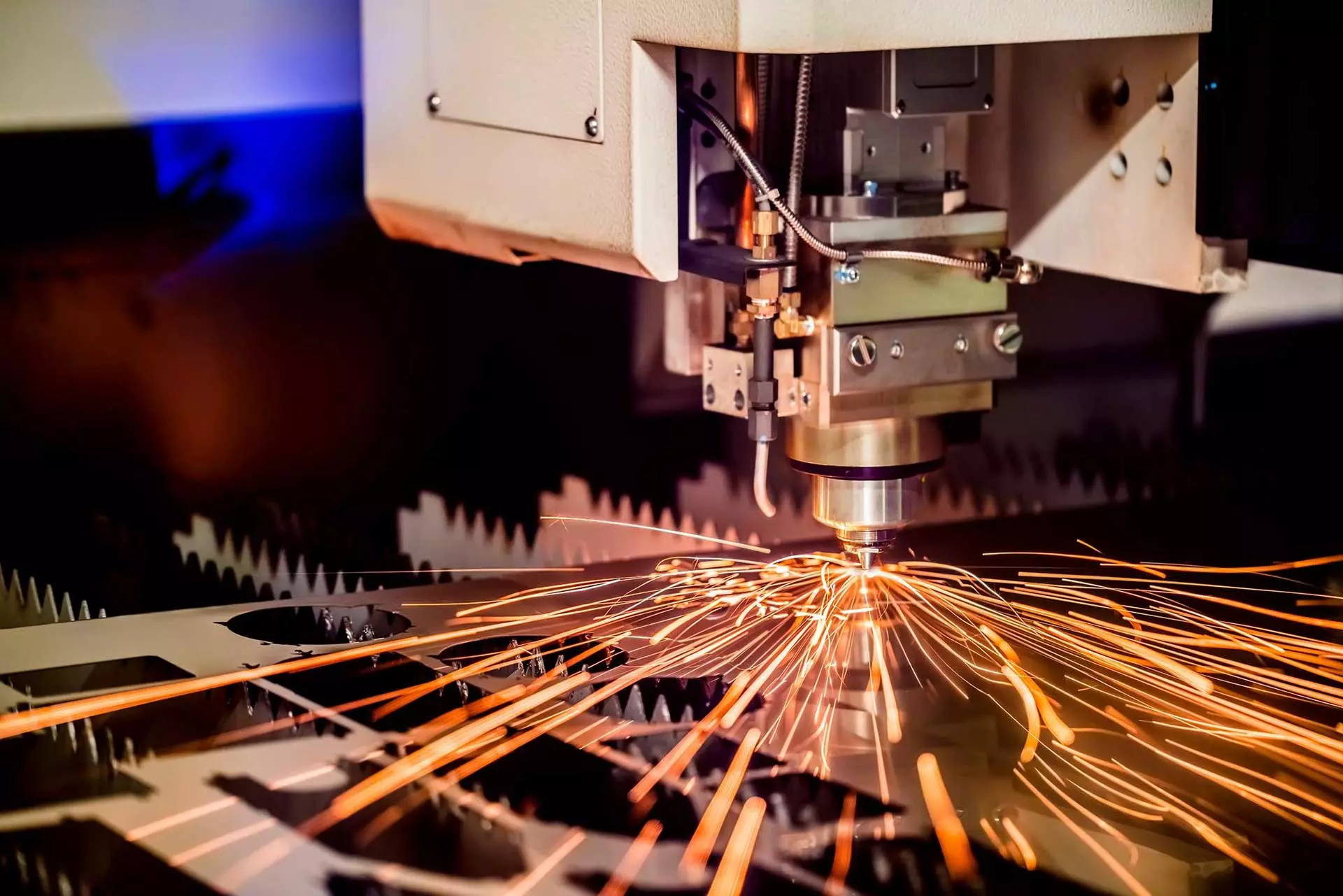

No matter if it involves precision surgical tools, texturing an implantable device, or marking delicate overwraps. Laser machine systems offer state-of-the-art solutions to mitigate risks, ensure regulatory compliance and advance patient safety.

CO2 laser systems boast low operating costs and can efficiently code surfaces such as curves or textures – even those covered by transparent overwraps – without incurring excessive material costs. They’re an affordable way to meet CDRH requirements for medical products.

CO2 laser systems boast low operating costs and can efficiently code surfaces such as curves or textures – even those covered by transparent overwraps – without incurring excessive material costs. They’re an affordable way to meet CDRH requirements for medical products.

Benefits

Laser technologies offer many medical device applications distinct advantages. This includes their ability to produce components with fine scale features such as precise cuts or welds; highly resolved markings for traceability purposes and rapid production times, along with flexible manufacturing processes with reduced heat input that can be tailored specifically to each application. Laser systems also allow direct field work or glovebox operations – including pacemaker laser welding and stripping off fluoropolymer jackets from electrodes used in neuromodulation devices implanted into the brain and spinal cord (which control Parkinson’s disease and essential tremor).

Medical-grade laser systems boast excellent power density, short pulse duration and stable beams with minimal thermal impact – ideal characteristics for the machining of metals and polymers, particularly new alloys like Nitinol. Their small size also enables their use in surgical or minimally invasive procedures like Lasik eye surgery – using fine laser beams to reshape cornea flaps for better vision – or laparoscopic interventions and surgeries such as cataract removal surgery or laparoscopic surgeries.

Medical-grade lasers can also be utilized for less invasive, less risky surgical and dermatological procedures, including tattoo and hair removal; skin resurfacing; liposuction; acne wart removal, wrinkle treatment and treating acne, warts and wrinkles among other cosmetic conditions. Their potential role in cancer prevention, cardiovascular diseases management as well as other serious ailments is currently under study.

Physicians are increasingly delegating laser use to non-physican personnel, including physician assistants and nurse practitioners, technicians, and support staff. Training should include selecting patients appropriately, preparing them properly for treatment, recording results appropriately, caring for complications as they arise, keeping records properly, as well as handling emergencies quickly. Furthermore,physicans must carry adequate malpractice insurance in case there are risks involved with delegating these devices to non-physican personnel.

Medical-grade lasers are also being utilized to develop and test innovative therapies, including non-invasive solutions for curing skin tumors, laser-induced thermolysis to damage blood vessels that feed cancer cells, and photodynamic therapy which uses light delivered directly onto tumor sites to kill or shrink cancerous tissue.

Medical-grade laser systems boast excellent power density, short pulse duration and stable beams with minimal thermal impact – ideal characteristics for the machining of metals and polymers, particularly new alloys like Nitinol. Their small size also enables their use in surgical or minimally invasive procedures like Lasik eye surgery – using fine laser beams to reshape cornea flaps for better vision – or laparoscopic interventions and surgeries such as cataract removal surgery or laparoscopic surgeries.

Medical-grade lasers can also be utilized for less invasive, less risky surgical and dermatological procedures, including tattoo and hair removal; skin resurfacing; liposuction; acne wart removal, wrinkle treatment and treating acne, warts and wrinkles among other cosmetic conditions. Their potential role in cancer prevention, cardiovascular diseases management as well as other serious ailments is currently under study.

Physicians are increasingly delegating laser use to non-physican personnel, including physician assistants and nurse practitioners, technicians, and support staff. Training should include selecting patients appropriately, preparing them properly for treatment, recording results appropriately, caring for complications as they arise, keeping records properly, as well as handling emergencies quickly. Furthermore,physicans must carry adequate malpractice insurance in case there are risks involved with delegating these devices to non-physican personnel.

Medical-grade lasers are also being utilized to develop and test innovative therapies, including non-invasive solutions for curing skin tumors, laser-induced thermolysis to damage blood vessels that feed cancer cells, and photodynamic therapy which uses light delivered directly onto tumor sites to kill or shrink cancerous tissue.

Applications

Laser technology has opened the doors for medical device innovations that were otherwise inconceivable with other technologies. Utilizing its focused light energy, lasers have enabled medical device innovation through novel capabilities that were simply impossible with other approaches. Their use allows the creation of microscopic features – cut widths smaller than human hair; spot welds with thermal damage zones barely detectable to the naked eye; highly resolved marking for surgical instruments and implants while adhering to strict regulatory standards of cleanliness and safety during all processes.

Laser’s high temporal coherence allows it to produce very narrow spots of heat energy that penetrate only the targeted materials’ surfaces, producing an accurate process without distortion from other technologies (such as mechanical punches) like mechanical punches. Furthermore, its ability to deliver precise heat at short wavelengths makes laser an efficient means for vaporizing materials and creating ablation holes through tissues.

From cardiac rhythm management devices and neuromodulation tools for Parkinson’s and essential tremor to orthopedic and hearing implants, many advanced medical devices utilize laser processing systems during their production. This includes using pulsed fiber lasers to seal pacemaker cartridges hermetically; stripping electrodes using short pulse lasers; laser marking UDI code data as sterilized; welding; wire stripping using short pulse lasers and marking devices sterile using laser welding; as well as marking them as such using laser processing systems.

As with any precision industrial process, the incorporation of laser processing into medical devices poses unique design challenges. Laser-based processes must be tightly managed and reliable in order to guarantee quality products; furthermore, the process should match scale, production volume, and application needs precisely. Integrate laser systems with order data handling interfaces in order to log every operation, eliminating compliance risk and providing traceability of all parts. As part of an optimal solution, lasers must have long runtimes with no maintenance requirements to maximize production output and decrease cycle times. Modern diode-pumped solid state lasers offer runtimes exceeding 10,000 operating hours without degradation in performance or efficiency, and gas-free solid-state lasers are now widely available for applications requiring an extended lifespan.

Laser’s high temporal coherence allows it to produce very narrow spots of heat energy that penetrate only the targeted materials’ surfaces, producing an accurate process without distortion from other technologies (such as mechanical punches) like mechanical punches. Furthermore, its ability to deliver precise heat at short wavelengths makes laser an efficient means for vaporizing materials and creating ablation holes through tissues.

From cardiac rhythm management devices and neuromodulation tools for Parkinson’s and essential tremor to orthopedic and hearing implants, many advanced medical devices utilize laser processing systems during their production. This includes using pulsed fiber lasers to seal pacemaker cartridges hermetically; stripping electrodes using short pulse lasers; laser marking UDI code data as sterilized; welding; wire stripping using short pulse lasers and marking devices sterile using laser welding; as well as marking them as such using laser processing systems.

As with any precision industrial process, the incorporation of laser processing into medical devices poses unique design challenges. Laser-based processes must be tightly managed and reliable in order to guarantee quality products; furthermore, the process should match scale, production volume, and application needs precisely. Integrate laser systems with order data handling interfaces in order to log every operation, eliminating compliance risk and providing traceability of all parts. As part of an optimal solution, lasers must have long runtimes with no maintenance requirements to maximize production output and decrease cycle times. Modern diode-pumped solid state lasers offer runtimes exceeding 10,000 operating hours without degradation in performance or efficiency, and gas-free solid-state lasers are now widely available for applications requiring an extended lifespan.

Technology

Laser materials processing systems have long been an integral component of medical devices that serve an array of essential purposes ranging from cardiac rhythm management and neuromodulation, orthopedics and hearing implants, laser materials processing systems for cardiac rhythm management and neuromodulation to orthotics and hearing implants. And as more complex devices emerge on the market, their production must enact an efficient manufacturing process in order to be produced cost effectively and reliably.

Laser systems’ precise marking ability makes them a suitable solution for medical device manufacturing applications. Metal and plastic surgical instruments are almost always marked with laser marking systems; plastic components in testing kits typically feature batch codes, scales and dial numbers laser etched; while drugs often feature sell-by dates that have also been laser etched onto them. As medical device companies face increasing consumer demands while adhering to stringent government regulations, their production lines must rely on processes that deliver fast, repeatable high-quality markups quickly.

Laser technology offers an effective and cost-efficient solution. Lasers produce intricate features in far less time than competing technologies can, without needing special cleanroom facilities for operation. Laser systems can replace traditional lithography or electroplating equipment without using harsh chemicals or hot surfaces – providing an alternative that’s just as efficient!

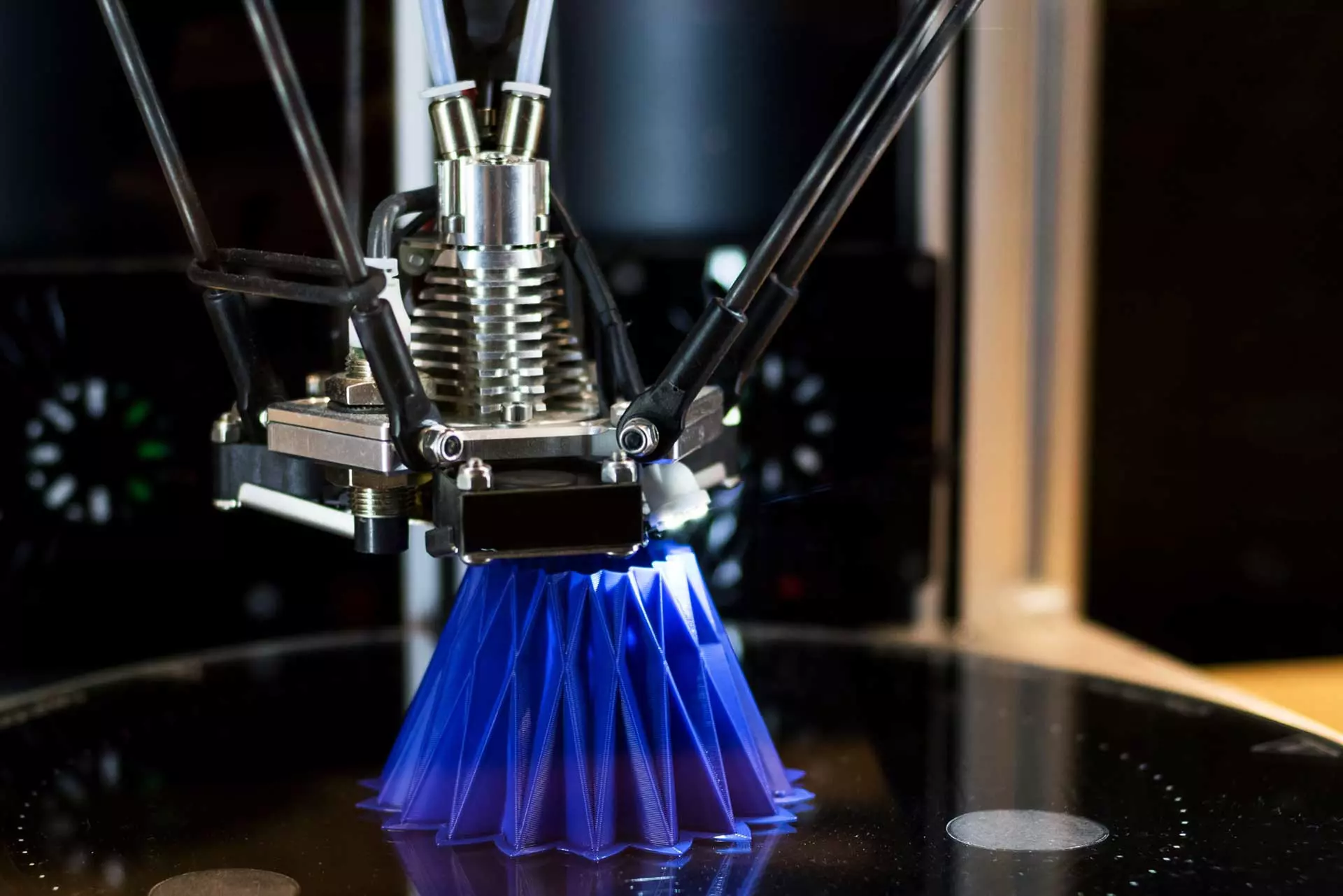

Lasers offer another important benefit when used for medical device fabrication: microscale and submicroscale features can be created quickly with lasers, providing significant time- and labor-savings over traditional fabrication techniques such as fused deposition modeling or wet etching which require time-intensive processes, especially when working with sensitive biomaterials.

Lasers play an essential role in creating new medical devices with enhanced functionalities, as well as in refining existing ones. Researchers at the University of Alberta recently developed a small device which can be implanted directly onto spinal cord injuries to enable injured individuals to walk again more freely; the goal is for as many students and companies to utilize this prototype so Alberta may lead the world in health-technology innovation.

These same technologies that have rendered medical devices more effective and accessible are simultaneously making them smaller, lighter, and cheaper – creating opportunities for manufacturers to innovate new and improved products ranging from tiny sensors that monitor heart activity to wearable devices that diagnose eye disorders – with so much potential in medicine!

Laser systems’ precise marking ability makes them a suitable solution for medical device manufacturing applications. Metal and plastic surgical instruments are almost always marked with laser marking systems; plastic components in testing kits typically feature batch codes, scales and dial numbers laser etched; while drugs often feature sell-by dates that have also been laser etched onto them. As medical device companies face increasing consumer demands while adhering to stringent government regulations, their production lines must rely on processes that deliver fast, repeatable high-quality markups quickly.

Laser technology offers an effective and cost-efficient solution. Lasers produce intricate features in far less time than competing technologies can, without needing special cleanroom facilities for operation. Laser systems can replace traditional lithography or electroplating equipment without using harsh chemicals or hot surfaces – providing an alternative that’s just as efficient!

Lasers offer another important benefit when used for medical device fabrication: microscale and submicroscale features can be created quickly with lasers, providing significant time- and labor-savings over traditional fabrication techniques such as fused deposition modeling or wet etching which require time-intensive processes, especially when working with sensitive biomaterials.

Lasers play an essential role in creating new medical devices with enhanced functionalities, as well as in refining existing ones. Researchers at the University of Alberta recently developed a small device which can be implanted directly onto spinal cord injuries to enable injured individuals to walk again more freely; the goal is for as many students and companies to utilize this prototype so Alberta may lead the world in health-technology innovation.

These same technologies that have rendered medical devices more effective and accessible are simultaneously making them smaller, lighter, and cheaper – creating opportunities for manufacturers to innovate new and improved products ranging from tiny sensors that monitor heart activity to wearable devices that diagnose eye disorders – with so much potential in medicine!

Safety

Lasers can be extremely powerful tools that can lead to serious injuries when misused. To reduce this risk, users of lasers should undergo proper training in their procedures before handling a laser device. It’s also crucial that users comply with all relevant ANSI and state regulations when operating lasers; furthermore, facilities should post clear safety signs throughout the facility to alert staff and patients of areas that should be addressed with extra caution.

Once again, let’s be real: no-one likes change – especially not their lifestyle choices! That’s why so many of us cling on for dear life when things start going south for some reason or another – or simply because life gets in the way. Laser devices are now widely utilized across a range of medical settings to treat dermatological ailments, like hair removal and skin resurfacing; pain management for arthritis treatment; cosmetic surgeries such as liposuction; soft tissue repairs such as wound healing or eye surgery. Laser-based devices have caused considerable concern among members of the public regarding both safety issues associated with their use and healthcare providers’ ability to conduct certain treatments without having to consult with physicians first. Concerns include false diagnoses such as melanoma or skin cancer; laser-based devices treating nonexistent diseases; and fraudulent claims made by users that certain treatments using these devices are effective when there is insufficient evidence supporting such claims.

States have responded to these concerns by creating various regulatory mechanisms governing the use of these devices, such as administrative rules, legislative changes and medical board recommendations.

Iowa has chosen to regulate these devices through the Cosmetology Board with a licensing program for estheticians, cosmetologists and electrologists. Only approved laser products and intense pulsed light devices related directly to their licensure may be used while providing services. Furthermore, Iowa law mandates specific training courses on using such devices which include significant safety components.

Several other states have developed regulatory schemes for laser-based devices that address physician oversight, training requirements, delegation to non-physician healthcare providers and complications/emergencies. This is intended to address uncontrolled use by healthcare providers who lack sufficient experience using them; an attempt at making changes statutory would likely face considerable difficulty due to implications on scope of practice as well as opposition from many professions that use laser devices.

Once again, let’s be real: no-one likes change – especially not their lifestyle choices! That’s why so many of us cling on for dear life when things start going south for some reason or another – or simply because life gets in the way. Laser devices are now widely utilized across a range of medical settings to treat dermatological ailments, like hair removal and skin resurfacing; pain management for arthritis treatment; cosmetic surgeries such as liposuction; soft tissue repairs such as wound healing or eye surgery. Laser-based devices have caused considerable concern among members of the public regarding both safety issues associated with their use and healthcare providers’ ability to conduct certain treatments without having to consult with physicians first. Concerns include false diagnoses such as melanoma or skin cancer; laser-based devices treating nonexistent diseases; and fraudulent claims made by users that certain treatments using these devices are effective when there is insufficient evidence supporting such claims.

States have responded to these concerns by creating various regulatory mechanisms governing the use of these devices, such as administrative rules, legislative changes and medical board recommendations.

Iowa has chosen to regulate these devices through the Cosmetology Board with a licensing program for estheticians, cosmetologists and electrologists. Only approved laser products and intense pulsed light devices related directly to their licensure may be used while providing services. Furthermore, Iowa law mandates specific training courses on using such devices which include significant safety components.

Several other states have developed regulatory schemes for laser-based devices that address physician oversight, training requirements, delegation to non-physician healthcare providers and complications/emergencies. This is intended to address uncontrolled use by healthcare providers who lack sufficient experience using them; an attempt at making changes statutory would likely face considerable difficulty due to implications on scope of practice as well as opposition from many professions that use laser devices.