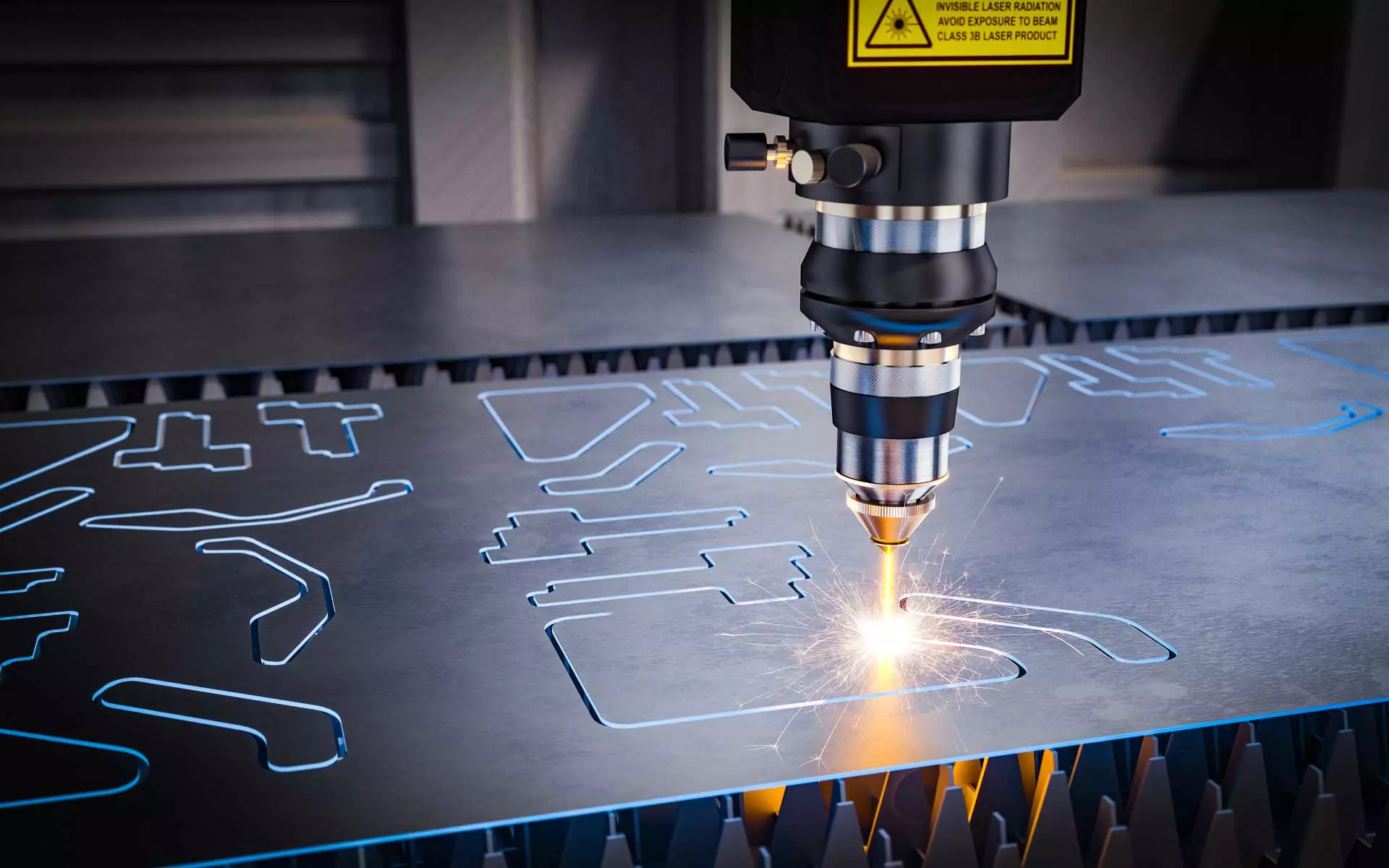

Laser scanning is the process of digitally measuring objects’ dimensions to create digital models, cutting down on manual labor costs while increasing precision and saving both time and money.

No matter whether it’s used for reading barcodes, projecting laser light shows, or welding car body components – laser scanning works using similar principles. In this article we’ll take a closer look at its inner workings.

No matter whether it’s used for reading barcodes, projecting laser light shows, or welding car body components – laser scanning works using similar principles. In this article we’ll take a closer look at its inner workings.

Triangulation

Laser scanning and imaging systems capture three-dimensional information by projecting a pattern of light onto objects or environments, deforming their surfaces as it travels across space to record shape and dimensions in what’s known as a point cloud data set – information which can then be digitized and used to construct three dimensional models of these environments or objects.

To produce these data sets, the scanner measures an object’s distance from a camera using triangulation. This process is both fast and accurate; cameras can scan thousands of points per second. Once collected, these points can then be assembled into digital models using software which calculates coordinates (x, y and z), providing measurements of where each point sits within three-dimensional space.

Traditional measurements were completed using tools that provided single point measurements, such as tape measures, piano wire, plumb bobs and total stations. Unfortunately, these methods are time consuming, taking days or months to fully capture an environment’s entirety and often producing discrepancies from user to user that compromise accuracy.

Triangulation was first utilized in land surveying, where it involved dividing an area into triangles and measuring their angles between sides to achieve accuracy and precision. Isosceles triangles must result for maximum precision and accuracy.

Different laser scanners utilize various technologies to interpret inbound signals — specifically time-of-flight scanners track how long it takes for an emitted laser signal to return from an object and phase shift scanners measure phase differences between outgoing and incoming signals. Time-of-flight scanners tend to offer greater versatility for midrange to long range applications.

Structured light projection is another method of triangulation that can be employed using laser scanners, taking advantage of the fact that objects reflect different amounts of light when seen from various angles. When this reflected light hits sensors within a scanning system, this data is then used to assess its 3D structure.

To produce these data sets, the scanner measures an object’s distance from a camera using triangulation. This process is both fast and accurate; cameras can scan thousands of points per second. Once collected, these points can then be assembled into digital models using software which calculates coordinates (x, y and z), providing measurements of where each point sits within three-dimensional space.

Traditional measurements were completed using tools that provided single point measurements, such as tape measures, piano wire, plumb bobs and total stations. Unfortunately, these methods are time consuming, taking days or months to fully capture an environment’s entirety and often producing discrepancies from user to user that compromise accuracy.

Triangulation was first utilized in land surveying, where it involved dividing an area into triangles and measuring their angles between sides to achieve accuracy and precision. Isosceles triangles must result for maximum precision and accuracy.

Different laser scanners utilize various technologies to interpret inbound signals — specifically time-of-flight scanners track how long it takes for an emitted laser signal to return from an object and phase shift scanners measure phase differences between outgoing and incoming signals. Time-of-flight scanners tend to offer greater versatility for midrange to long range applications.

Structured light projection is another method of triangulation that can be employed using laser scanners, taking advantage of the fact that objects reflect different amounts of light when seen from various angles. When this reflected light hits sensors within a scanning system, this data is then used to assess its 3D structure.

Point Clouds

Laser scanning and imaging systems capture accurate 3D digital representations of natural and built environments known as point clouds.

Point clouds can be defined simply as an assembly of points in 3-D space, each point defined in terms of X, Y and Z coordinates that represents an underlying sampled surface. Each data point often receives its own ID number as well as GPS time stamping information – but other attributes (e.g. reflectance value or color) may also be included with each point cloud data point.

With terrestrial laser scanners, only surfaces within reach of their beam are captured; these readings are known as line-of-sight (LOS) readings. For the most precise data possible, surveyors should scan multiple positions and stitch together all their information with extreme accuracy using multisensor fusion – either using physical registration targets on the ground to guide software or finding commonalities between scans which will then automatically align them together.

Reconstructed images created from laser scanning can be utilized in numerous applications, including as-builts, infrastructure inspection, construction planning and project management. Not only is laser scanning fast and precise; its ability to produce 2D CAD sheets and 3D BIM models also enables surveyors to complete projects faster than with traditional hand tools like total stations.

Surveyors are increasingly turning to drones as a tool for collecting point clouds, particularly when surveying buildings or complex structures where terrestrial scanners cannot capture them properly. This has created some confusion amongst professionals as to whether this technology will eventually replace traditional laser scanning, leading some people to question if we’re transitioning towards becoming a “drone-first” society.

Laser scanning provides numerous uses that cameras alone simply cannot match; that is where professional laser scanning services come into their own. A trusted service will turn point clouds produced by a laser scanner into CAD drawings which engineers and architects can then use in their work, for instance for building information modelling purposes.

Point clouds can be defined simply as an assembly of points in 3-D space, each point defined in terms of X, Y and Z coordinates that represents an underlying sampled surface. Each data point often receives its own ID number as well as GPS time stamping information – but other attributes (e.g. reflectance value or color) may also be included with each point cloud data point.

With terrestrial laser scanners, only surfaces within reach of their beam are captured; these readings are known as line-of-sight (LOS) readings. For the most precise data possible, surveyors should scan multiple positions and stitch together all their information with extreme accuracy using multisensor fusion – either using physical registration targets on the ground to guide software or finding commonalities between scans which will then automatically align them together.

Reconstructed images created from laser scanning can be utilized in numerous applications, including as-builts, infrastructure inspection, construction planning and project management. Not only is laser scanning fast and precise; its ability to produce 2D CAD sheets and 3D BIM models also enables surveyors to complete projects faster than with traditional hand tools like total stations.

Surveyors are increasingly turning to drones as a tool for collecting point clouds, particularly when surveying buildings or complex structures where terrestrial scanners cannot capture them properly. This has created some confusion amongst professionals as to whether this technology will eventually replace traditional laser scanning, leading some people to question if we’re transitioning towards becoming a “drone-first” society.

Laser scanning provides numerous uses that cameras alone simply cannot match; that is where professional laser scanning services come into their own. A trusted service will turn point clouds produced by a laser scanner into CAD drawings which engineers and architects can then use in their work, for instance for building information modelling purposes.

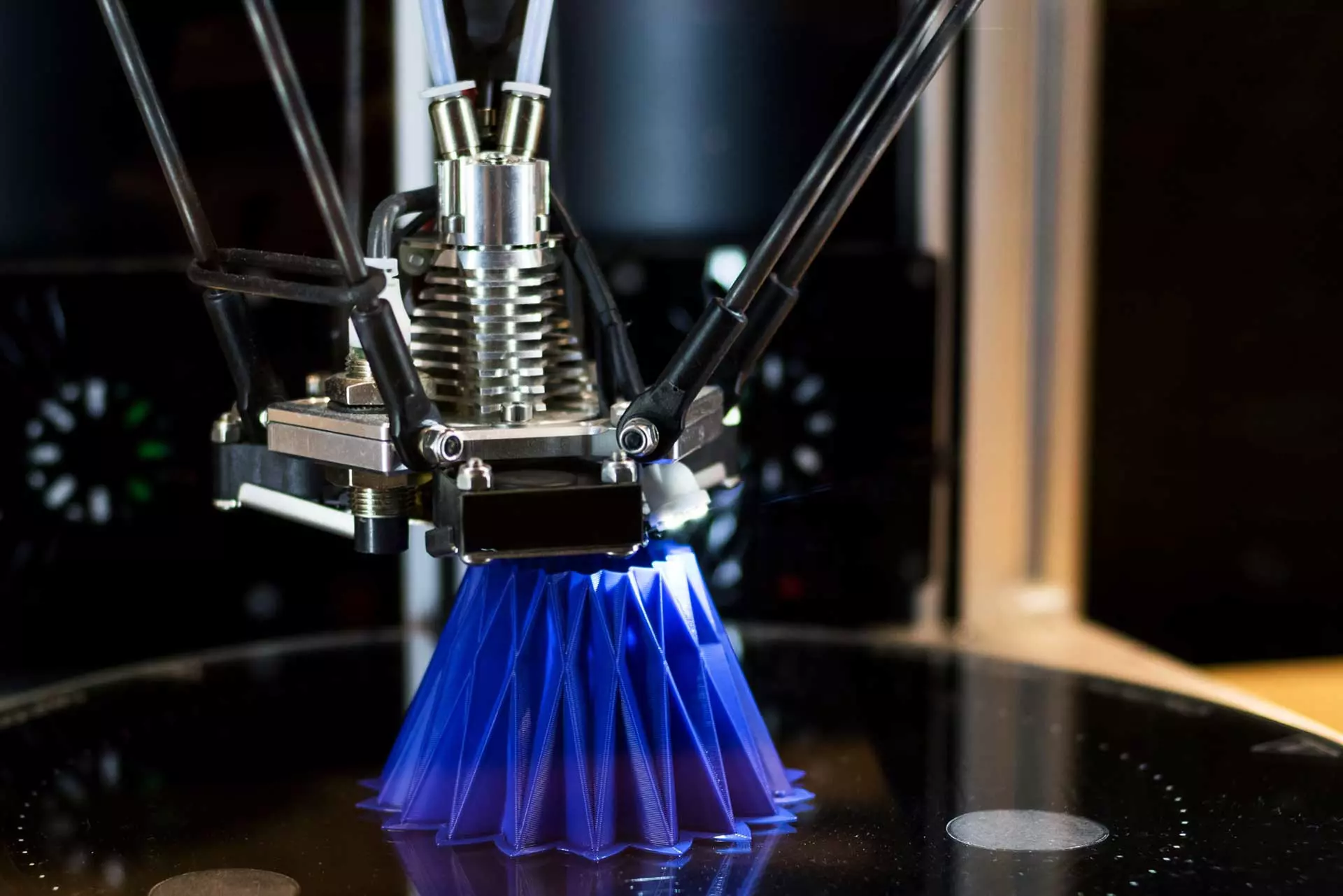

3D Models

Laser scanners use nondestructive measurement techniques to reconstruct objects’ 3D shapes in 3 dimensions and define their position in space. As standalone devices that are noncontact and nondestructive, laser scanners can be handheld, stationary and tripod mounted; attached to mobile vehicles such as cars, boats or trains or even airborne drones; or attached directly onto marine vessels (marine vessels and submarines) or airborne (drones).

There are various kinds of laser scanning technologies that vary. Two of the most prevalent are time of flight and phase shift technologies based on triangulation principles. Time of flight instruments emit laser light bursts that are measured as they return back to them with different speeds by sensors attached to time of flight instruments; using this data, distance calculations between points on objects can be performed and produced as “point clouds”, producing millions of data points in total.

Advantages of this method include its versatility; from sub-1m distance up to half a kilometer. However, maximum accuracy and resolution may be limited by an instrument’s field of view (LOS) and point density; solid objects cast shadows which reduce this density; thus necessitating multiple scans from various angles so as to cover occluded areas.

Phase shift systems utilize phase analysis to measure reflected signals by comparing their phases with both emitted and received signals, with some systems offering caption rates as high as one million points per second.

Laser scanning’s rapid measurement rates make it more cost-effective than other measuring tools, enabling companies to rapidly turn data into 3D models and decrease prototype cycle times by getting measurements right first time around.

Laser scanning technology can also aid quality control during production. By comparing a 3D model against its CAD counterpart, teams can easily identify any elements outside tolerance and address them before they become a larger problem.

There are various kinds of laser scanning technologies that vary. Two of the most prevalent are time of flight and phase shift technologies based on triangulation principles. Time of flight instruments emit laser light bursts that are measured as they return back to them with different speeds by sensors attached to time of flight instruments; using this data, distance calculations between points on objects can be performed and produced as “point clouds”, producing millions of data points in total.

Advantages of this method include its versatility; from sub-1m distance up to half a kilometer. However, maximum accuracy and resolution may be limited by an instrument’s field of view (LOS) and point density; solid objects cast shadows which reduce this density; thus necessitating multiple scans from various angles so as to cover occluded areas.

Phase shift systems utilize phase analysis to measure reflected signals by comparing their phases with both emitted and received signals, with some systems offering caption rates as high as one million points per second.

Laser scanning’s rapid measurement rates make it more cost-effective than other measuring tools, enabling companies to rapidly turn data into 3D models and decrease prototype cycle times by getting measurements right first time around.

Laser scanning technology can also aid quality control during production. By comparing a 3D model against its CAD counterpart, teams can easily identify any elements outside tolerance and address them before they become a larger problem.

Accuracy

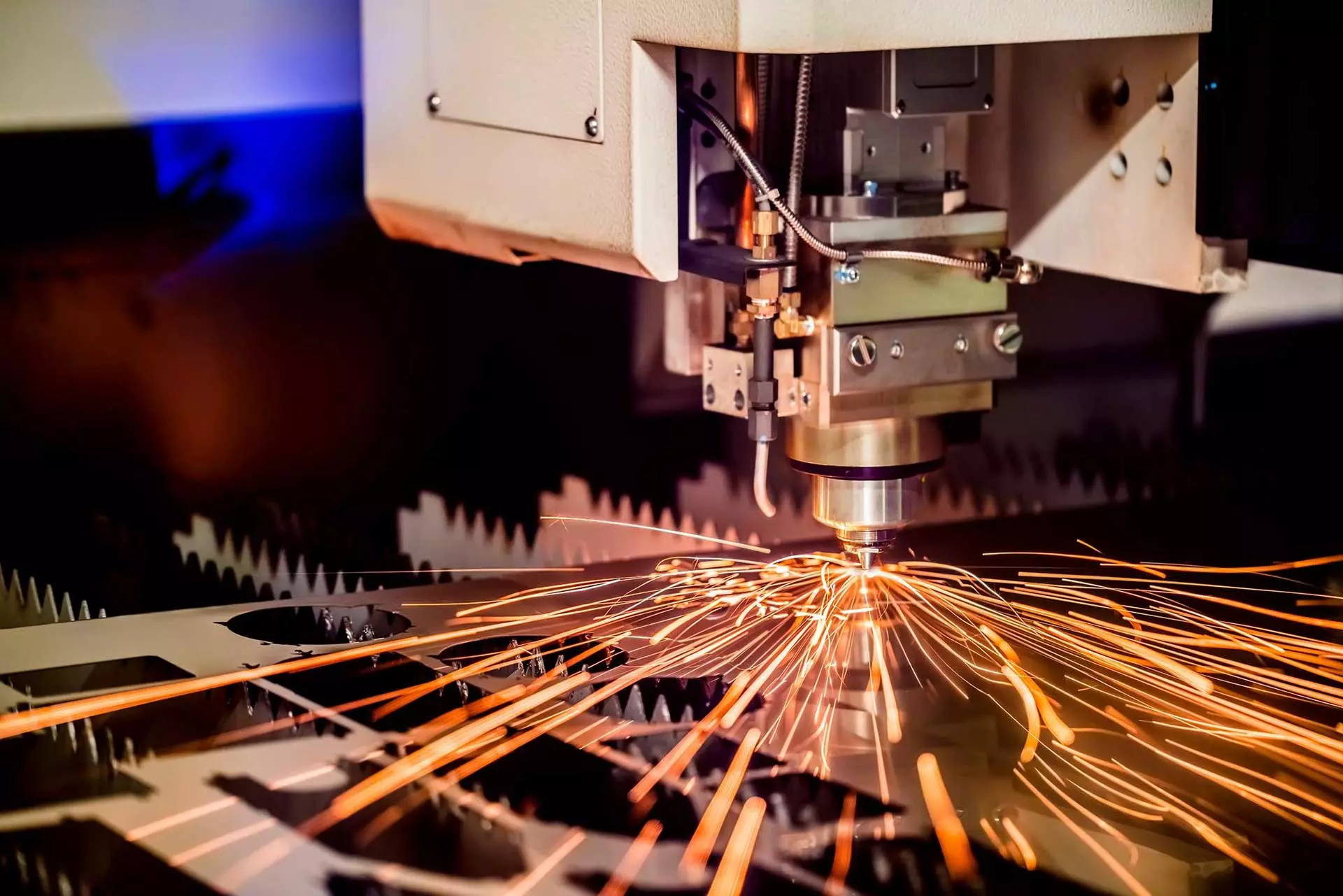

Laser scanning and imaging systems operate across a range of distances, from as close as a few feet up to multiple kilometers. Their range depends on the type of scanner being used; time-of-flight scanners work similarly to laser range finders by emitting laser pulses that reflect off an object or surface before returning back into a sensor on the scanner and recording their return signal – then calculating distances accordingly.

Phase-shift scanners work differently by modulating the intensity of laser pulses to generate different wave forms that reflect off an object or surface and cause different reflection patterns to return signals, creating an offset in those returned signals that allows distance calculations to take place. These systems are best utilized for medium-range scanning needs such as large pumps, automobiles or industrial equipment.

Both types of scanners produce accurate results for various objects and surfaces; however, their precision does depend on factors like the quality of lens used on their cameras or even where laser light reflects off surfaces.

Laser scanning technology is used primarily as an accurate means of collecting site information for design, construction and maintenance projects. This reduces manual labor requirements while also helping prevent errors from recurring, as well as providing flexible planning throughout a project’s course.

As a result, it can help companies reduce labor costs and eliminate rework, as well as shorten project timelines by giving contractors immediate information on what needs to be corrected or altered.

As technology improves, its widespread adoption across various industries increases. Gilbane, for instance, has seen substantial cost savings and timeline improvements from importing laser scans into Revit models; additionally, laser scanning increases level of accuracy for construction projects thus helping reduce rework while simultaneously increasing quality.

Phase-shift scanners work differently by modulating the intensity of laser pulses to generate different wave forms that reflect off an object or surface and cause different reflection patterns to return signals, creating an offset in those returned signals that allows distance calculations to take place. These systems are best utilized for medium-range scanning needs such as large pumps, automobiles or industrial equipment.

Both types of scanners produce accurate results for various objects and surfaces; however, their precision does depend on factors like the quality of lens used on their cameras or even where laser light reflects off surfaces.

Laser scanning technology is used primarily as an accurate means of collecting site information for design, construction and maintenance projects. This reduces manual labor requirements while also helping prevent errors from recurring, as well as providing flexible planning throughout a project’s course.

As a result, it can help companies reduce labor costs and eliminate rework, as well as shorten project timelines by giving contractors immediate information on what needs to be corrected or altered.

As technology improves, its widespread adoption across various industries increases. Gilbane, for instance, has seen substantial cost savings and timeline improvements from importing laser scans into Revit models; additionally, laser scanning increases level of accuracy for construction projects thus helping reduce rework while simultaneously increasing quality.