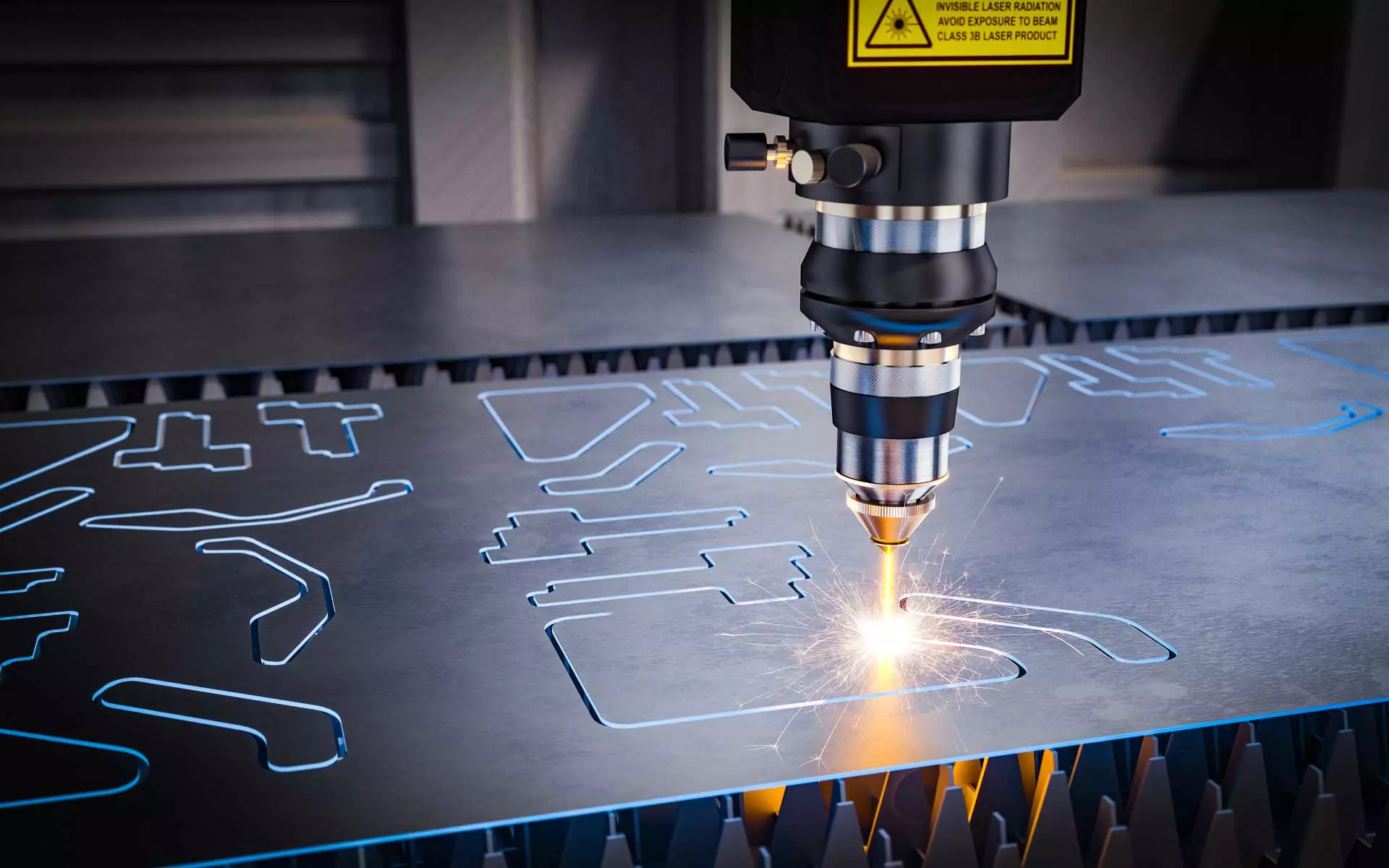

Laser marking technology creates legible and durable markings on components’ surfaces without harming them – perfect for automotive components, electronics and many other industries.

Laser marking machines use sealed-tube systems that emit different wavelengths of laser light to mark various types of materials. While they’re best used on metals, they also work effectively for marking paper and polymers.

Laser marking machines use sealed-tube systems that emit different wavelengths of laser light to mark various types of materials. While they’re best used on metals, they also work effectively for marking paper and polymers.

High-Speed

Laser marking creates permanent marks on components and products by using laser light beams with different energies to etch, cut, scorch, anneal or discolor their surfaces depending on energy levels. Laser marking machines are capable of marking materials such as steel, titanium, aluminum, copper and ceramics as well as plastics, paper cardboard glass wood with text (such as serial numbers part numbers unique ID codes ), machine readable data (2D Data Matrix etc), graphics etc.

Laser markers offer manufacturers an effective means of meeting traceability requirements quickly and without compromising print quality, creating highly visible codes that can easily be read by barcode scanners and cameras. As such, they have become popular choices among food producers when meeting traceability obligations are critical compliance concerns.

Laser markers offer more than high speed; in addition to their speedy capabilities they also offer excellent contrast between marked and unmarked surfaces of products, ensuring legible marking even on those with complex shapes or dark hues – something traditional printing methods such as dot peen or inkjet marking don’t do. This gives laser markers an edge over traditional printing methods like dot peening or inkjet marking can’t match.

KEYENCE’s laser marking systems utilize cutting-edge technology designed to meet the rigorous demands of industrial production lines. Their 100-Watt fiber laser is custom built for use on various materials including metals and plastics; its fiber tip can mark Datamatrix, alphanumeric and logo codes on numerous types of surfaces up to 1,000 feet/min!

Laser marking offers superior contrast compared to other technologies such as inkjet or dot peen marking, which makes it especially helpful when marking difficult-to-read surfaces like curves and uneven terrain. Furthermore, it’s an excellent choice for marking nonporous materials like glossed cardboard and varnished surfaces as well as plastic and anodized aluminum surfaces that do not allow ink to penetrate deeply enough for inkjet marking or dot peen marking to take effect.

Your laser marker choice depends on your production requirements and type of mark you need to create. Knowing what characteristics characterize your products will help narrow down models by wavelength, wattage and integration style.

Laser markers offer manufacturers an effective means of meeting traceability requirements quickly and without compromising print quality, creating highly visible codes that can easily be read by barcode scanners and cameras. As such, they have become popular choices among food producers when meeting traceability obligations are critical compliance concerns.

Laser markers offer more than high speed; in addition to their speedy capabilities they also offer excellent contrast between marked and unmarked surfaces of products, ensuring legible marking even on those with complex shapes or dark hues – something traditional printing methods such as dot peen or inkjet marking don’t do. This gives laser markers an edge over traditional printing methods like dot peening or inkjet marking can’t match.

KEYENCE’s laser marking systems utilize cutting-edge technology designed to meet the rigorous demands of industrial production lines. Their 100-Watt fiber laser is custom built for use on various materials including metals and plastics; its fiber tip can mark Datamatrix, alphanumeric and logo codes on numerous types of surfaces up to 1,000 feet/min!

Laser marking offers superior contrast compared to other technologies such as inkjet or dot peen marking, which makes it especially helpful when marking difficult-to-read surfaces like curves and uneven terrain. Furthermore, it’s an excellent choice for marking nonporous materials like glossed cardboard and varnished surfaces as well as plastic and anodized aluminum surfaces that do not allow ink to penetrate deeply enough for inkjet marking or dot peen marking to take effect.

Your laser marker choice depends on your production requirements and type of mark you need to create. Knowing what characteristics characterize your products will help narrow down models by wavelength, wattage and integration style.

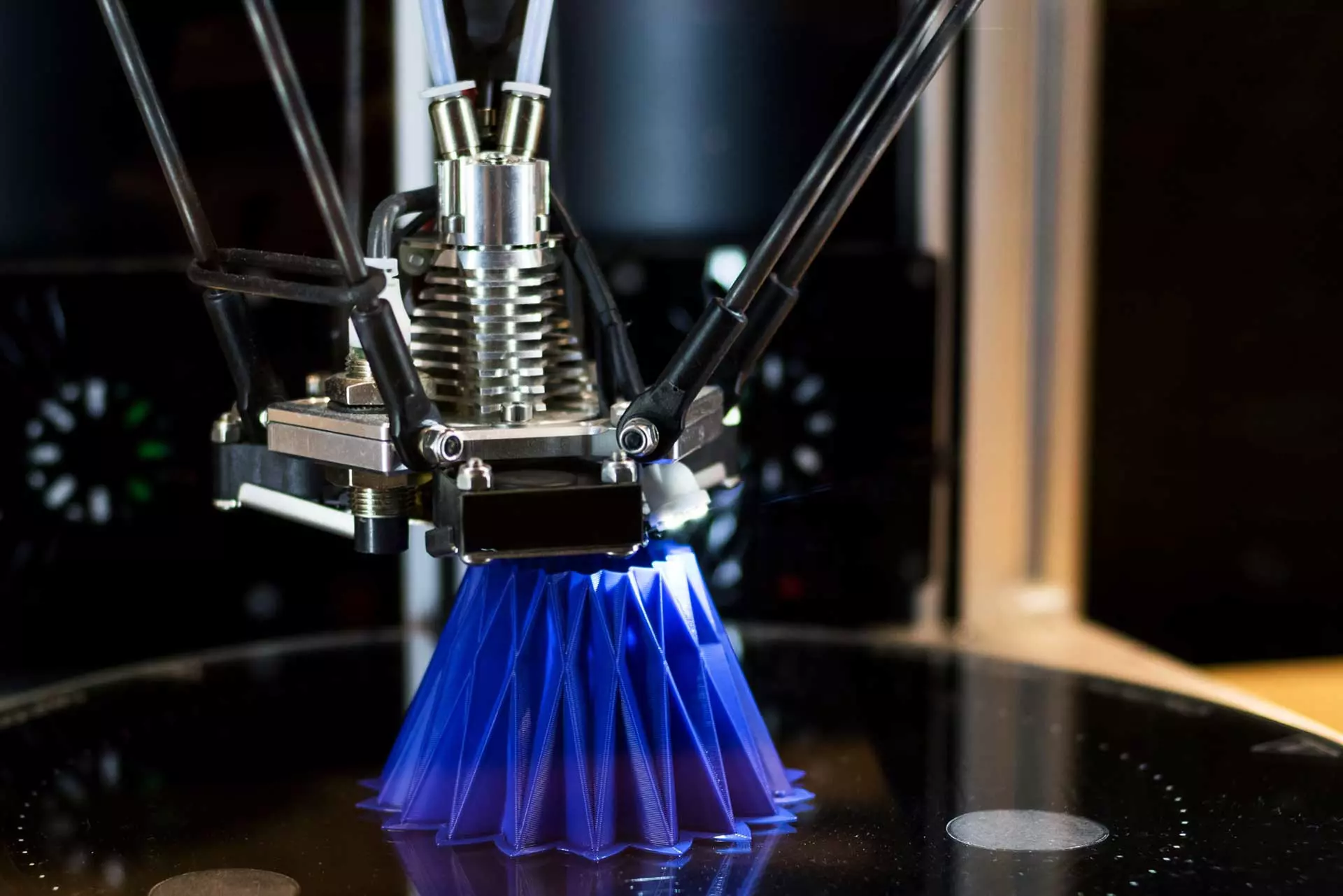

High-Quality

Laser marking systems use focused beams of high-energy light that produce permanent, visible, and legible marks on metals and plastics with permanent, visible, and legible marks that are permanent, visible, readable, flexible enough for marking various codes such as 2D barcodes, human-readable alphanumeric codes, logos on products, parts and components; laser marker technology can even create these symbols and codes on both flat surfaces as well as those buried into parts – perfect for marking metal parts for their use as components!

As opposed to inkjet printing and pad-printing, laser marking technology creates permanent marks that cannot be erased over time or fade away with exposure to harsh environments. Furthermore, unlike chemical etching or inkjet printing which require consumables for maintenance costs savings purposes.

KEYENCE laser markers come equipped with three-axis beam control, allowing them to mark in three dimensions and scan and mark products with complex 3-D surfaces such as cylinders or cones that traditional systems cannot handle. Furthermore, they can compensate for part variations or mounting restrictions without needing physical adjustments on equipment.

Quality marks from laser markers depend on their wavelength, power and type of laser used. Single mode lasers feature more uniform power distribution compared to multi-mode ones for better mark quality; and DPSS lasers boast the highest energy density allowing them to produce better-quality marks more rapidly.

Laser marking outpaces other coding methods in terms of marking speed, such as pad-printing or chemical etching, with no risk of product contamination or residue being left behind. Furthermore, unlike inkjet or pad-printing systems, laser marking systems can process multiple lines faster than a traditional printer would be able to.

Laser marking technology’s versatility enables it to be utilized across industries, from automotive and manufacturing to plastics/polymers/metals marking. Furthermore, it is capable of marking products or parts with various codes like 2D barcodes, human-readable serial numbers and VIN numbers; not to mention plastics/polymers and metals alike.

As opposed to inkjet printing and pad-printing, laser marking technology creates permanent marks that cannot be erased over time or fade away with exposure to harsh environments. Furthermore, unlike chemical etching or inkjet printing which require consumables for maintenance costs savings purposes.

KEYENCE laser markers come equipped with three-axis beam control, allowing them to mark in three dimensions and scan and mark products with complex 3-D surfaces such as cylinders or cones that traditional systems cannot handle. Furthermore, they can compensate for part variations or mounting restrictions without needing physical adjustments on equipment.

Quality marks from laser markers depend on their wavelength, power and type of laser used. Single mode lasers feature more uniform power distribution compared to multi-mode ones for better mark quality; and DPSS lasers boast the highest energy density allowing them to produce better-quality marks more rapidly.

Laser marking outpaces other coding methods in terms of marking speed, such as pad-printing or chemical etching, with no risk of product contamination or residue being left behind. Furthermore, unlike inkjet or pad-printing systems, laser marking systems can process multiple lines faster than a traditional printer would be able to.

Laser marking technology’s versatility enables it to be utilized across industries, from automotive and manufacturing to plastics/polymers/metals marking. Furthermore, it is capable of marking products or parts with various codes like 2D barcodes, human-readable serial numbers and VIN numbers; not to mention plastics/polymers and metals alike.

Cost-Effective

Laser marking is a non-contact, damage-free process that does not use heat to mark materials. As such, it does not need to cool parts down after marking which allows for high-speed production and does not alter texture of parts with minimal heat-affected areas around each mark compared with inkjet printing, which often leaves parts bleeding or deforming over time. This makes laser printing more effective than its inkjet counterpart as both techniques create permanent marks without leaving residual heat-affected zones surrounding each mark – saving both time and resources when compared with its counterpart inkjet printers which may leave residual inkjet printing that causes parts bleeding smudge or deform

Laser markers offer an ideal alternative to code stickers or inkjet printers in terms of cost-cutting operations; with little maintenance requirements and easy nozzle reusing for different products and materials. As a result, their costs of use become far more cost-effective for large production runs than their counterparts.

Laser markers focus their power into a single-mode beam with point symmetry that produces highly defined markings with clear contrast against surrounding materials, guaranteeing legible and clear results even after time has passed. Furthermore, these devices are suitable for marking various substrates including polymers and metals at wavelengths well-suited to their absorption by each material being marked.

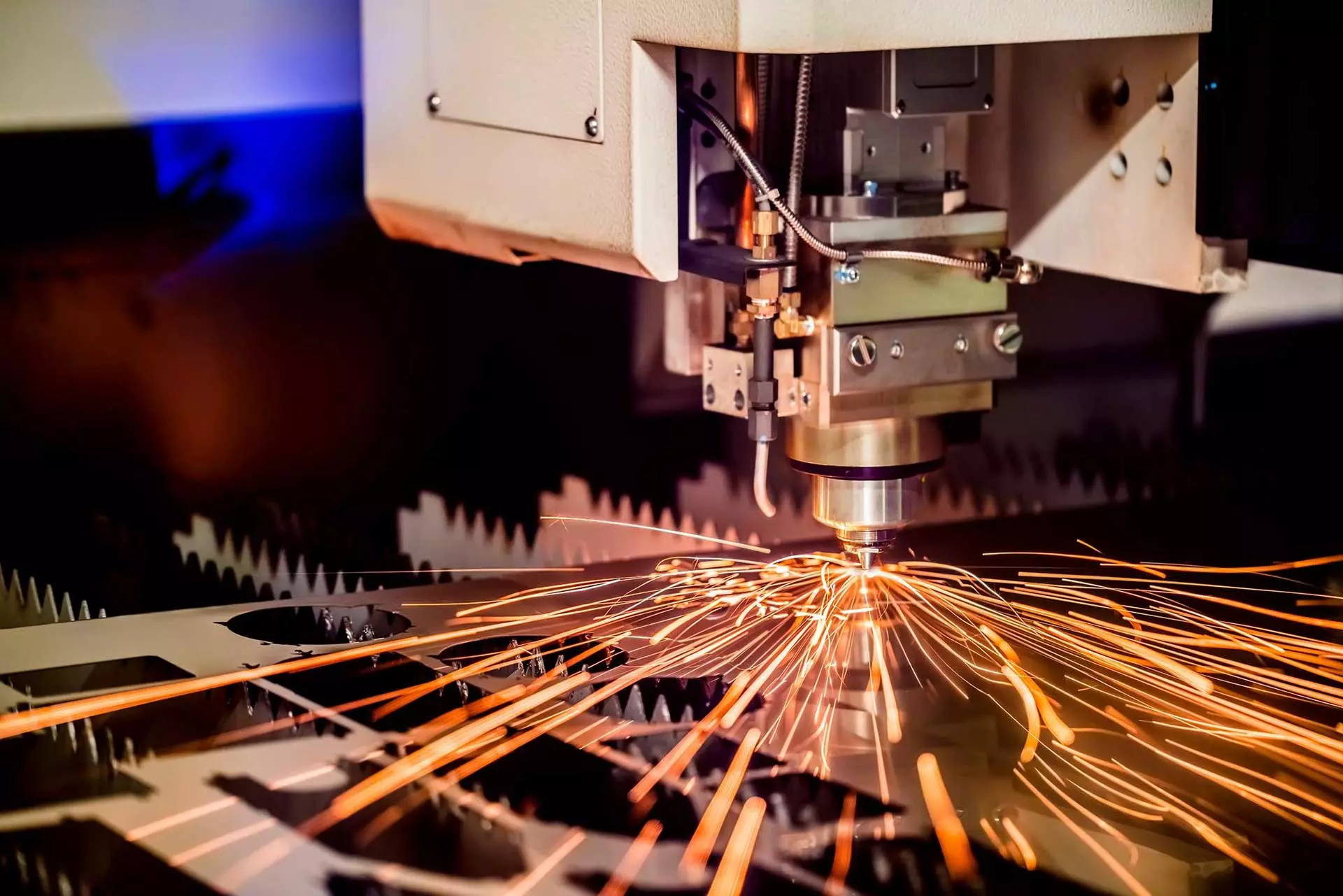

CO2 lasers are ideal for processing organic materials like papers and wood, while fiber and Nd:YAG lasers work well on various metal grades. Depending on your material choice, lasers may be used either for ablation or etching to achieve your desired mark.

Laser etching, which creates dark marks on surfaces without altering them significantly, is widely used in medical instruments and stainless steels for marking purposes. Additionally, this technique has become particularly popular within the automotive industry due to its ability to mark serial numbers, bar codes, expiration dates and best-before dates on components.

Laser technology offers more than just marking and etching capabilities – it is also ideal for cutting, drilling and surface reformation, making it a highly flexible tool in production lines that require both coding and processing.

Laser markers offer an ideal alternative to code stickers or inkjet printers in terms of cost-cutting operations; with little maintenance requirements and easy nozzle reusing for different products and materials. As a result, their costs of use become far more cost-effective for large production runs than their counterparts.

Laser markers focus their power into a single-mode beam with point symmetry that produces highly defined markings with clear contrast against surrounding materials, guaranteeing legible and clear results even after time has passed. Furthermore, these devices are suitable for marking various substrates including polymers and metals at wavelengths well-suited to their absorption by each material being marked.

CO2 lasers are ideal for processing organic materials like papers and wood, while fiber and Nd:YAG lasers work well on various metal grades. Depending on your material choice, lasers may be used either for ablation or etching to achieve your desired mark.

Laser etching, which creates dark marks on surfaces without altering them significantly, is widely used in medical instruments and stainless steels for marking purposes. Additionally, this technique has become particularly popular within the automotive industry due to its ability to mark serial numbers, bar codes, expiration dates and best-before dates on components.

Laser technology offers more than just marking and etching capabilities – it is also ideal for cutting, drilling and surface reformation, making it a highly flexible tool in production lines that require both coding and processing.

Long-Lasting

Laser marking is an eco-friendly non-contact method of marking that does not cause internal stress or wear on workpieces. Furthermore, no harmful corrosive chemicals or dust or poisonous gases are used compared to traditional marking methods; making laser marking an environment-friendly alternative. Laser marking enables legible information creation without impacting integrity of workpiece or altering appearance; it also has strong anti-counterfeiting capabilities and boasts strong anti-counterfeiting capabilities.

Lasers are commonly employed for product labelling and marking applications, including QR codes, serial numbers, bar codes, part numbers, manufacturing dates, best before or expiry dates, company logos, maintenance due dates and other text or symbols. Laser marking allows products to be more easily scanned or photographed than their ink equivalent, providing greater traceability – an especially critical function when used on industrial products.

Different materials react differently to laser light, so selecting an appropriate laser system for your application is of utmost importance. KEYENCE’s laser marker range includes sealed-tube laser systems designed to mark non-metal surfaces as well as ND:YAG lasers which feature galvo-steered light beams capable of accurately engraving or discoloring surfaces with high efficiency and accuracy.

Metals tend to absorb and reflect laser energy, making them ideal for laser marking applications. To mark metal surfaces with laser marking applications, the laser heats it and changes its color through oxidization; leaving behind a permanent mark which cannot be erased or modified later on. Laser marking applications have become widely utilized within medical, aerospace, automotive and electronics industries.

Plastics and polymers can be marked using laser marking by melting their surface with heat. This creates an easy-to-read contrast that’s called carbon migration or foaming and works best on lighter colored products like paper, wood, leather or packaging materials; dark-colored objects do not lend themselves to this method due to grey markings with lower contrast with their surroundings.

Lasers are commonly employed for product labelling and marking applications, including QR codes, serial numbers, bar codes, part numbers, manufacturing dates, best before or expiry dates, company logos, maintenance due dates and other text or symbols. Laser marking allows products to be more easily scanned or photographed than their ink equivalent, providing greater traceability – an especially critical function when used on industrial products.

Different materials react differently to laser light, so selecting an appropriate laser system for your application is of utmost importance. KEYENCE’s laser marker range includes sealed-tube laser systems designed to mark non-metal surfaces as well as ND:YAG lasers which feature galvo-steered light beams capable of accurately engraving or discoloring surfaces with high efficiency and accuracy.

Metals tend to absorb and reflect laser energy, making them ideal for laser marking applications. To mark metal surfaces with laser marking applications, the laser heats it and changes its color through oxidization; leaving behind a permanent mark which cannot be erased or modified later on. Laser marking applications have become widely utilized within medical, aerospace, automotive and electronics industries.

Plastics and polymers can be marked using laser marking by melting their surface with heat. This creates an easy-to-read contrast that’s called carbon migration or foaming and works best on lighter colored products like paper, wood, leather or packaging materials; dark-colored objects do not lend themselves to this method due to grey markings with lower contrast with their surroundings.