Free-space acousto-optic modulators convert input light into various orders through periodic changes in refractive index, with this effect controlled by the strength of an RF control signal.

A video signal from source 116 is fed into two AOM’s 110 and 112, activating both of them simultaneously with one amplifier 118.

A video signal from source 116 is fed into two AOM’s 110 and 112, activating both of them simultaneously with one amplifier 118.

High Diffraction Efficiency

An acousto-optic modulator involves passing light through a transparent crystal or piece of glass connected to an electric driver, and vibrated periodically by an electronic signal; this causes periodic density changes which result in refractive index variations that cause light to be scattered into multiple orders, providing the opportunity for modulating laser beam intensity by selectively transmitting only first order diffracted light from this medium.

Utilizing multiple transducers within an acousto-optic mod can enhance its diffraction efficiency, creating multiple first order diffracted beams that overlap, thus producing a significantly increased contrast ratio. Another way to boost an acousto-optic’s diffraction efficiency is using it in “chopper mode”, using frequency modulated driving signals to sweep linearly the diffracted beam positions throughout an array.

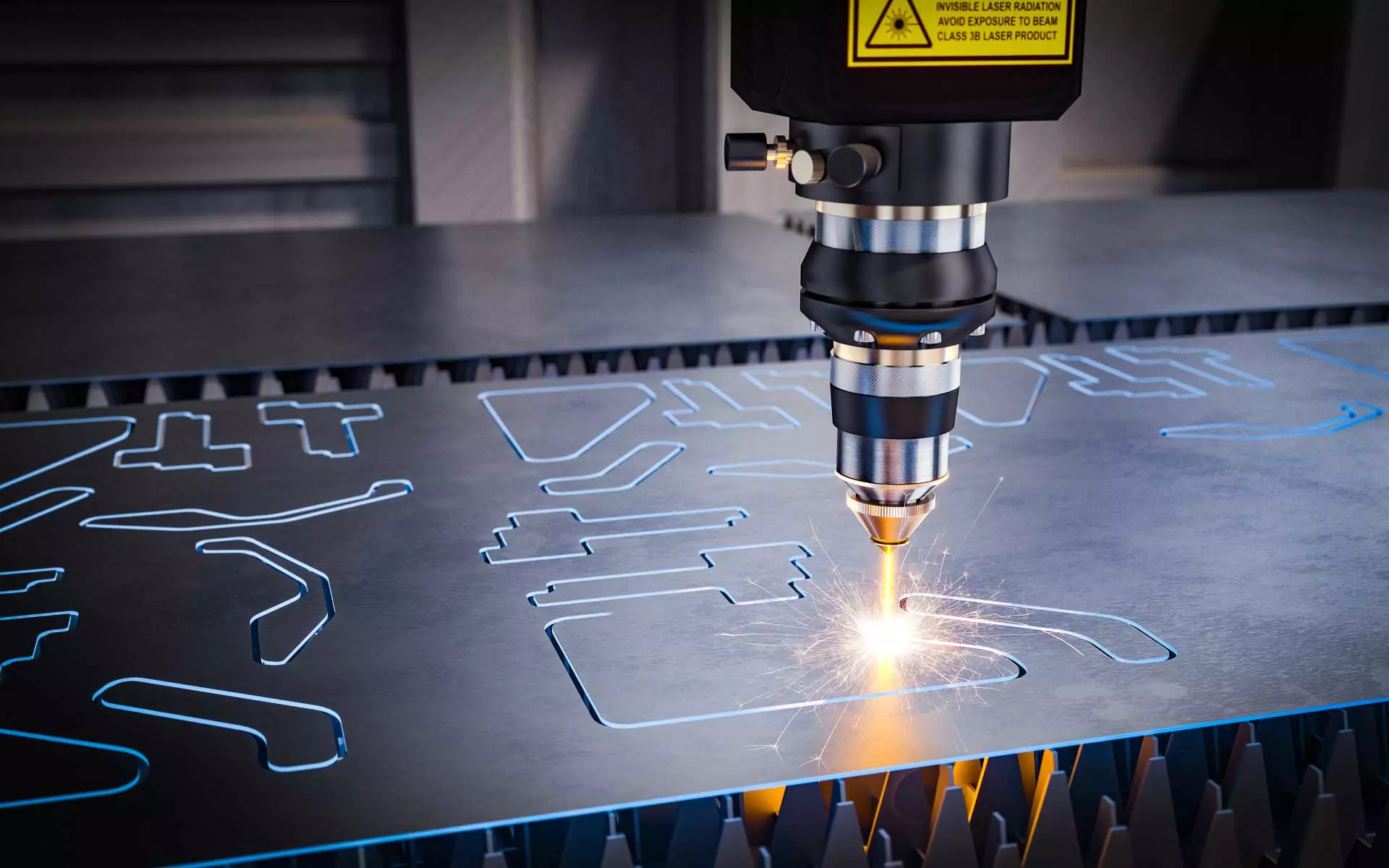

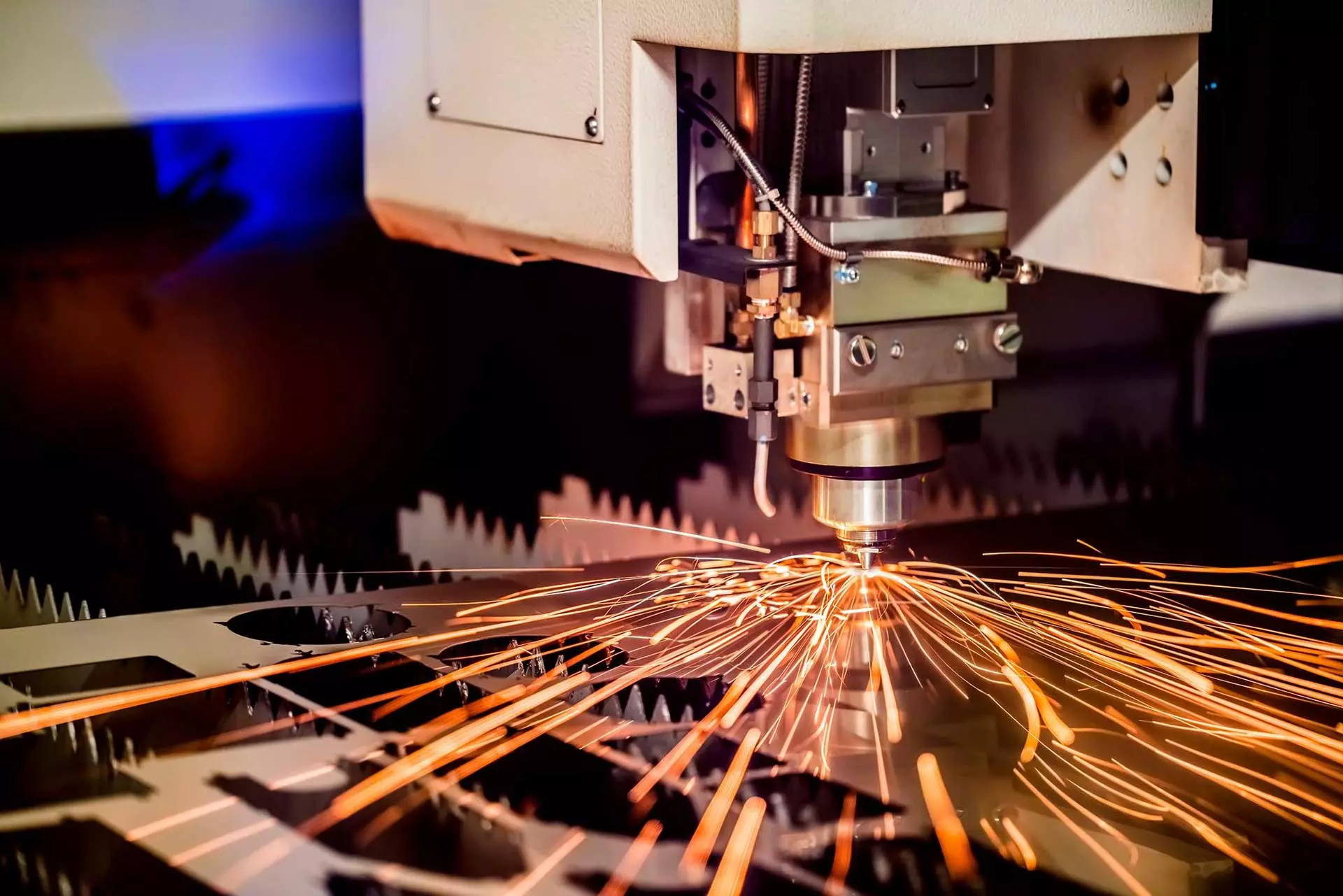

These acousto-optic devices can be used to generate energy-efficient laser pulses at gigahertz frequencies with high repetition rates. Furthermore, these devices can generate extremely short light pulses through Q-switching; an approach often employed in laser cutting or other manufacturing techniques.

A polarized laser beam is directed through a polarizing beam combiner and half-wave plate into an acousto-optic modulator where it is transmitted, but reflected back. Through use of a second waveplate, its polarization is rotated 90deg; as a result, its reflection has parallel polarization as that of its transmitted beam, enabling passage through with low losses through modulator.

Utilizing multiple transducers within an acousto-optic mod can enhance its diffraction efficiency, creating multiple first order diffracted beams that overlap, thus producing a significantly increased contrast ratio. Another way to boost an acousto-optic’s diffraction efficiency is using it in “chopper mode”, using frequency modulated driving signals to sweep linearly the diffracted beam positions throughout an array.

These acousto-optic devices can be used to generate energy-efficient laser pulses at gigahertz frequencies with high repetition rates. Furthermore, these devices can generate extremely short light pulses through Q-switching; an approach often employed in laser cutting or other manufacturing techniques.

A polarized laser beam is directed through a polarizing beam combiner and half-wave plate into an acousto-optic modulator where it is transmitted, but reflected back. Through use of a second waveplate, its polarization is rotated 90deg; as a result, its reflection has parallel polarization as that of its transmitted beam, enabling passage through with low losses through modulator.

High Modulation Rate

The acousto-optic effect leverages vibrational sound waves to change the refractive index of transparent crystal or glass materials, changing their refractive index and altering their refractive index to alter laser beam intensity or frequency and frequency shifters respectively. Acoustic deflectors may also be utilized as devices capable of altering spatial directions of laser beams.

AOMs typically consist of lithium niobate (LiNbO3) crystals driven by an electric signal to produce soundwaves within their cell that cause periodic fluctuations in medium density, producing scattering patterns which act like Bragg diffraction gratings, splitting an incoming beam into two diffracted output beams.

One drawback of AOMs is their relatively low modulation rate, determined by how quickly their acoustic waves can traverse a laser beam based on both diameter and velocity of its sound waves within.

Multiple transducers may be combined to increase the modulation rate of AOMs. Each transducer can be driven using frequency-modulated driving signals for maximum flexibility when positioning first-order diffracted beams from different angles.

Thus, an AOM can be used to generate high-intensity laser pulses at an ultrafast repetition rate – perfect for active Q-switching, mode locking of ultrafast lasers, and optical fiber amplifiers.

AOMs typically consist of lithium niobate (LiNbO3) crystals driven by an electric signal to produce soundwaves within their cell that cause periodic fluctuations in medium density, producing scattering patterns which act like Bragg diffraction gratings, splitting an incoming beam into two diffracted output beams.

One drawback of AOMs is their relatively low modulation rate, determined by how quickly their acoustic waves can traverse a laser beam based on both diameter and velocity of its sound waves within.

Multiple transducers may be combined to increase the modulation rate of AOMs. Each transducer can be driven using frequency-modulated driving signals for maximum flexibility when positioning first-order diffracted beams from different angles.

Thus, an AOM can be used to generate high-intensity laser pulses at an ultrafast repetition rate – perfect for active Q-switching, mode locking of ultrafast lasers, and optical fiber amplifiers.

High Power Efficiency

An acousto-optic modulator involves the interaction between a laser beam and high frequency ultrasonic soundwave in an optically polished block of glass or crystal (the interaction medium). By vibrating the crystal in certain ways, sound waves can be made to reflect off of the laser beam in what is known as Bragg diffraction; quickly turning on and off acoustic wave can rapidly deflect and refract off laser beam (digital modulation); by changing amplitude of wave intensity of modulator can modulate intensity of deflected beam.

In order to attain a high modulation rate, high diffraction efficiency is needed; however, increasing it also raises driving power requirements. A two-arm acousto-optic modulator configuration could be used instead. Here the IDT is placed outside both arms of a Mach-Zehnder interferometer waveguide so only 50% of converted acoustic energy reaches both waveguides and can interact with laser beam.

Brimrose has designed and successfully tested an optical device utilizing lithium niobate crystal. The device can achieve chopper mode operation with repetition frequencies between 1 gigahertz and 10 gigahertz; in addition, its light intensity diffraction efficiency ranges between 7-10% at drive electric power levels of only 1.0 W.

A free space acousto-optic modulator (AOM) is electronically programmable using a microprocessor connected to an STBR series RF driver – featuring all the components needed for analog or digital control of AOM via analog/digital input control, all housed within an environmentally safe package offering superior resistance against temperature and humidity fluctuations.

In order to attain a high modulation rate, high diffraction efficiency is needed; however, increasing it also raises driving power requirements. A two-arm acousto-optic modulator configuration could be used instead. Here the IDT is placed outside both arms of a Mach-Zehnder interferometer waveguide so only 50% of converted acoustic energy reaches both waveguides and can interact with laser beam.

Brimrose has designed and successfully tested an optical device utilizing lithium niobate crystal. The device can achieve chopper mode operation with repetition frequencies between 1 gigahertz and 10 gigahertz; in addition, its light intensity diffraction efficiency ranges between 7-10% at drive electric power levels of only 1.0 W.

A free space acousto-optic modulator (AOM) is electronically programmable using a microprocessor connected to an STBR series RF driver – featuring all the components needed for analog or digital control of AOM via analog/digital input control, all housed within an environmentally safe package offering superior resistance against temperature and humidity fluctuations.

Low Noise

An acousto-optic modulator can be an effective tool for reducing noise in laser beams, however there are limitations associated with its performance. In order to use such an approach effectively, your system must be able to tolerate delays between arriving light at the modulator and its signal being recorded by amplifier. Furthermore, your laser beam must pass through it without distortion and minimal loss.

Standard AOMs feature laser beams interacting with ultrasonic soundwaves at ultrasonic frequencies within an optically polished block of crystal or glass (the interaction medium). This interaction is possible thanks to Bragg diffraction, deflecting when laser light collides with acoustic waves until they dissipate; once deflected it passes undeviated through undeviated; digital modulation can quickly create and destroy deflected laser beams as sound field switches on and off rapidly; by varying the amplitude of acoustic waves intensity can also vary accordingly (analogue modulation).

Diffraction processes vary polarization-wise depending on the design of an AOM (latic or shear waves, isotropic or anisotropic material etc). To enable operation for both linearly polarized laser beams as well as circularly polarized input laser beams an acousto-optic beam splitter may be employed.

An alternative way of creating the same effect using DC-AOMs is to generate two independent acousto-optic beams; however, one will have a different modulation profile than the first, which can lead to variations in beam size and intensity as well as delays between AOM-1 outputs and AOM-2 outputs which may interfere with pulse risetime.

Standard AOMs feature laser beams interacting with ultrasonic soundwaves at ultrasonic frequencies within an optically polished block of crystal or glass (the interaction medium). This interaction is possible thanks to Bragg diffraction, deflecting when laser light collides with acoustic waves until they dissipate; once deflected it passes undeviated through undeviated; digital modulation can quickly create and destroy deflected laser beams as sound field switches on and off rapidly; by varying the amplitude of acoustic waves intensity can also vary accordingly (analogue modulation).

Diffraction processes vary polarization-wise depending on the design of an AOM (latic or shear waves, isotropic or anisotropic material etc). To enable operation for both linearly polarized laser beams as well as circularly polarized input laser beams an acousto-optic beam splitter may be employed.

An alternative way of creating the same effect using DC-AOMs is to generate two independent acousto-optic beams; however, one will have a different modulation profile than the first, which can lead to variations in beam size and intensity as well as delays between AOM-1 outputs and AOM-2 outputs which may interfere with pulse risetime.

High Speed

When an RF driver is applied, an acousto-optic modulator rapidly alternates between an unpowered flat mirror state and a powered diffractive state; providing high-speed modulation of laser beam intensity up to 200 MHz depending on model.

An AOM operates when an electric signal causes a piezoelectric crystal or piece of glass to vibrate with vibrational waves generated from piezoelectric crystals or pieces of glass, creating changes in density which induce periodic fluctuations of its refractive index, producing a periodic change of refractive index and eventually producing a periodic Bragg diffraction grating pattern that when incident at an appropriate angle scatters light while some passes straight through it.

This results in a modulated output light beam with only minimal (1%) optical insertion loss. This approach represents an impressive advancement over mechanical methods that use wedge-shaped beam splitters to generate two equal intensity output beams from a single input source.

At such high speeds, there is one drawback to AOM’s high speed performance: its rise time limits its modulation rate. This is because soundwave travel time across an optical beam depends on factors like beam size and the interaction medium’s acoustic velocity.

Brimrose provides free space acousto-optic modulators that use Fourier mode coupling to achieve high modulation frequencies at low rise times, using devices called Polarizing Beam Combiners and Half Wave Plates with AOMs utilizing this technique to reverse polarity of output light reflected back through an AOM, increasing diffraction efficiency through multiple passes through it.

An AOM operates when an electric signal causes a piezoelectric crystal or piece of glass to vibrate with vibrational waves generated from piezoelectric crystals or pieces of glass, creating changes in density which induce periodic fluctuations of its refractive index, producing a periodic change of refractive index and eventually producing a periodic Bragg diffraction grating pattern that when incident at an appropriate angle scatters light while some passes straight through it.

This results in a modulated output light beam with only minimal (1%) optical insertion loss. This approach represents an impressive advancement over mechanical methods that use wedge-shaped beam splitters to generate two equal intensity output beams from a single input source.

At such high speeds, there is one drawback to AOM’s high speed performance: its rise time limits its modulation rate. This is because soundwave travel time across an optical beam depends on factors like beam size and the interaction medium’s acoustic velocity.

Brimrose provides free space acousto-optic modulators that use Fourier mode coupling to achieve high modulation frequencies at low rise times, using devices called Polarizing Beam Combiners and Half Wave Plates with AOMs utilizing this technique to reverse polarity of output light reflected back through an AOM, increasing diffraction efficiency through multiple passes through it.