Acousto-optic devices use sound waves to amplitude modulate, deflect or shift the optical frequency of light. An electronic signal generates this acoustic wave which is then introduced into transparent materials through piezoelectric transducers.

Optic components that employ the acousto-optic effect have many applications in various fields, including laser beam shaping and steering, optical tweezers and microscopy.

Optic components that employ the acousto-optic effect have many applications in various fields, including laser beam shaping and steering, optical tweezers and microscopy.

Tellurium Dioxide

Tellurium Dioxide, commonly referred to as paratellurite or TeO2, is an acousto-optic material widely utilized in various acousto-optic devices, including modulators, imaging devices, splitters, deflectors and AOTF (acousto-optic tunable filters), laser Q-switches and spectrum analyzers.

Tellurite is an excellent material to use in acousto-optical devices due to its impressive figure of merit; this allows it to diffuse incident light more effectively than other acousto-optic materials, and particularly impressive at wavelengths between 330 to 450 nanometers; TeO2 figures of merit can often be found in AOTFs for confocal microscopy applications.

TeO2 boasts excellent acousto-optic properties that can be utilized to craft various acousto-optic elements; among these elements are modulators and splitters.

Acoustic-optic devices offer several distinct advantages when used for compact spectral analysis instruments, particularly their small size, making them suitable for compact instruments with limited space for analysis. Unfortunately, however, these components can be susceptible to thermal effects that compromise diffraction efficiency and cause beam shift.

Therefore, when designing an acousto-optic element it must generate low frequency, low amplitude acoustic waves of sufficient frequency and amplitude that it can effectively create the desired optical effect. A glass composition with high acousto-optic figure or merit and minimal loss is preferred as this allows maximum power output without significant loss in sound transmission.

The present acousto-optic glass compositions are tailored to display an outstanding combination of desirable properties in their acousto-optc properties, including a high figure of merit designated M2 and low attenuation rates. These properties can be achieved using compositions containing at least 92% tellurium dioxide along with sodium oxide or potassium oxide as well as lithium oxide in minor quantities, in order to attain these goals.

Tellurite-containing acousto-optic compositions can be easily prepared using finely divided powders of both tellurium dioxide and alkali metal oxides, combined and physically combined before being physically combined in a gold crucible between 750 to 950 deg C for melting.

Tellurite is an excellent material to use in acousto-optical devices due to its impressive figure of merit; this allows it to diffuse incident light more effectively than other acousto-optic materials, and particularly impressive at wavelengths between 330 to 450 nanometers; TeO2 figures of merit can often be found in AOTFs for confocal microscopy applications.

TeO2 boasts excellent acousto-optic properties that can be utilized to craft various acousto-optic elements; among these elements are modulators and splitters.

Acoustic-optic devices offer several distinct advantages when used for compact spectral analysis instruments, particularly their small size, making them suitable for compact instruments with limited space for analysis. Unfortunately, however, these components can be susceptible to thermal effects that compromise diffraction efficiency and cause beam shift.

Therefore, when designing an acousto-optic element it must generate low frequency, low amplitude acoustic waves of sufficient frequency and amplitude that it can effectively create the desired optical effect. A glass composition with high acousto-optic figure or merit and minimal loss is preferred as this allows maximum power output without significant loss in sound transmission.

The present acousto-optic glass compositions are tailored to display an outstanding combination of desirable properties in their acousto-optc properties, including a high figure of merit designated M2 and low attenuation rates. These properties can be achieved using compositions containing at least 92% tellurium dioxide along with sodium oxide or potassium oxide as well as lithium oxide in minor quantities, in order to attain these goals.

Tellurite-containing acousto-optic compositions can be easily prepared using finely divided powders of both tellurium dioxide and alkali metal oxides, combined and physically combined before being physically combined in a gold crucible between 750 to 950 deg C for melting.

Fused Silica

Fused silica (or synthetic fused silica) is an increasingly popular material for use in acousto-optic devices due to its ability to transmit UV light without absorbing it, helping increase conversion efficiency. Furthermore, fused silica provides protection from high temperatures or can even shift optical frequencies of devices.

Fused silica comes in many shapes and forms, including tubing, rods, and blocks of various sizes. This glass features low thermal expansion rates and chemical inertness to most substances. Furthermore, it’s very shock resistant; heating/cooling cycles can occur rapidly without cracking.

Aluminum Oxide (AO) is an extremely transparent material with very high density that can be used to craft lightweight lenses for acousto-optic applications. Furthermore, this biomedical grade material has chemical inertness against most acids for biomedical uses.

Additionally, it can be formed into thick sheets for use in thin film semiconductor fabrication, and offers exceptional heat resistance making it the ideal material to etch microchips or photolithography substrates.

As it can withstand extremely high temperatures and has excellent bonding properties, silicone rubber has proven itself a superior material for machining applications.

Fused silica glass can be tempered or annealed to produce different types of glasses, including tinted, transparent and colored options. This process involves heating to a specific temperature before cooling at an even lower one in order to prevent crystallization of crystalized materials within it.

Fused silica-matrix composites with carbon fiber slurry that contains SiC particles as filler can also be made into unidirectional fiber matrices for use in acousto-optic horns and other acoustic devices, providing unidirectional fibers with support structures for unidirectional fibers used in these devices. Hot pressing provides for high flexural strength – an essential feature in large devices like these acoustics devices.

Fused silica has numerous advantages over borosilicate glasses like Tempax and Pyrex in terms of manufacturing cost reduction, thermal conductivity reduction and insulation options that prevent overheating or cooling issues – making it the ideal material for acousto-optics applications such as acousto-optics. Furthermore, fused silica’s highly versatile properties enable it to transmit deep ultraviolet wavelengths as well as near infrared radiation without creating large volumes of waste material or cutting costs.

Fused silica comes in many shapes and forms, including tubing, rods, and blocks of various sizes. This glass features low thermal expansion rates and chemical inertness to most substances. Furthermore, it’s very shock resistant; heating/cooling cycles can occur rapidly without cracking.

Aluminum Oxide (AO) is an extremely transparent material with very high density that can be used to craft lightweight lenses for acousto-optic applications. Furthermore, this biomedical grade material has chemical inertness against most acids for biomedical uses.

Additionally, it can be formed into thick sheets for use in thin film semiconductor fabrication, and offers exceptional heat resistance making it the ideal material to etch microchips or photolithography substrates.

As it can withstand extremely high temperatures and has excellent bonding properties, silicone rubber has proven itself a superior material for machining applications.

Fused silica glass can be tempered or annealed to produce different types of glasses, including tinted, transparent and colored options. This process involves heating to a specific temperature before cooling at an even lower one in order to prevent crystallization of crystalized materials within it.

Fused silica-matrix composites with carbon fiber slurry that contains SiC particles as filler can also be made into unidirectional fiber matrices for use in acousto-optic horns and other acoustic devices, providing unidirectional fibers with support structures for unidirectional fibers used in these devices. Hot pressing provides for high flexural strength – an essential feature in large devices like these acoustics devices.

Fused silica has numerous advantages over borosilicate glasses like Tempax and Pyrex in terms of manufacturing cost reduction, thermal conductivity reduction and insulation options that prevent overheating or cooling issues – making it the ideal material for acousto-optics applications such as acousto-optics. Furthermore, fused silica’s highly versatile properties enable it to transmit deep ultraviolet wavelengths as well as near infrared radiation without creating large volumes of waste material or cutting costs.

Lithium Niobate

Lithium Niobate (LiNbO3) is an ideal material for acousto-optic devices due to its large E-O/NLO/AO coefficient, high transparency window and stable chemical and physical properties. Applications for LiNbO3 range from laser beam guidance, optical fiber communications, piezoelectric sensors and modulators all the way through piezoelectric sensors and modulators.

These properties, together with its wide transmission window and large AO/NLO coefficients, have made this lens ideal for many photonic applications in particular the development of ultra-low loss LN nanophotonic waveguides and microresonators.

Periodically poled lithium niobate (PPLN) has been extensively researched in nonlinear optics and frequency conversion, and as an acousto-optic modulator material. PPLN boasts one of the strongest electro-optic coefficients r33 at 1064nm as well as strong acousto-optic (AO) coupling strengths among all other acousto-optic crystals; additionally it is widely studied with applications including frequency conversion, frequency shifting, quantum entanglement, nonlinear beam shaping among others. Among PPLN materials which shows promise is periodic polarized LN gratings which also exhibit these characteristics;

Recently, fabricating ultralow-loss highly confined LN nanophotonic waveguides has emerged as an area of research interest and several key technologies are being explored to meet this objective.

These techniques include: 1.) Smart Cut Method for X-cut and Z-cut LNOI films to reduce ion implantation-induced defects; and 2.) ICP Reactive Ion Etching Optimization of over-cladding layers on LNOI samples that have been shown to increase propagation loss in photonic circuits.

3.) Metal electrodes can be placed between the substrate and LN waveguide to take advantage of its r33 electro-optic coefficient for nonlinear optical performance in periodically poled lithium niobate. This has proven successful.

4.) Utilizing Y-cut LNOI films with higher acousto-optic coupling strength is another attractive method to creating unreleased acousto-optic devices, though a thick buried oxide layer on such an LN film may decrease electromechanical coupling strength of an acousto-optic device.

The global acousto-optic devices market is forecasted to experience significant expansion during the forecast period, due to increasing demand from verticals such as aeroplane-to-ground phase keyed optical communication systems, IT & Telecom services providers, biomedical applications and others.

These properties, together with its wide transmission window and large AO/NLO coefficients, have made this lens ideal for many photonic applications in particular the development of ultra-low loss LN nanophotonic waveguides and microresonators.

Periodically poled lithium niobate (PPLN) has been extensively researched in nonlinear optics and frequency conversion, and as an acousto-optic modulator material. PPLN boasts one of the strongest electro-optic coefficients r33 at 1064nm as well as strong acousto-optic (AO) coupling strengths among all other acousto-optic crystals; additionally it is widely studied with applications including frequency conversion, frequency shifting, quantum entanglement, nonlinear beam shaping among others. Among PPLN materials which shows promise is periodic polarized LN gratings which also exhibit these characteristics;

Recently, fabricating ultralow-loss highly confined LN nanophotonic waveguides has emerged as an area of research interest and several key technologies are being explored to meet this objective.

These techniques include: 1.) Smart Cut Method for X-cut and Z-cut LNOI films to reduce ion implantation-induced defects; and 2.) ICP Reactive Ion Etching Optimization of over-cladding layers on LNOI samples that have been shown to increase propagation loss in photonic circuits.

3.) Metal electrodes can be placed between the substrate and LN waveguide to take advantage of its r33 electro-optic coefficient for nonlinear optical performance in periodically poled lithium niobate. This has proven successful.

4.) Utilizing Y-cut LNOI films with higher acousto-optic coupling strength is another attractive method to creating unreleased acousto-optic devices, though a thick buried oxide layer on such an LN film may decrease electromechanical coupling strength of an acousto-optic device.

The global acousto-optic devices market is forecasted to experience significant expansion during the forecast period, due to increasing demand from verticals such as aeroplane-to-ground phase keyed optical communication systems, IT & Telecom services providers, biomedical applications and others.

Gallium Phosphide

Gallium phosphide (GaP) is one of the most frequently utilized materials in acousto-optic devices, being an indirect band gap semiconductor with a lattice constant of 0.5445nm and electron mobility of 110 cm2/V-s and hole mobility of 75 cm2/V-s respectively.

This compound has found widespread application in electronics applications, from CMOS and RF/V/A switches to LED components and sensing and imaging applications.

Additionally, silicon is often utilized as the material in tunable filters and acousto-optic deflectors, devices used to control laser beam amplitude. They may also be utilized during manufacturing of optical fibers, holograms, or photonic circuits.

Acousto-optic devices are projected to experience significant growth between 2016-2022. These devices offer reliable and economical laser light modulation solutions.

These devices are typically controlled with electrical inputs to transducers that emit acoustic waves. These waves travel through crystals to deflect laser beams; their wavelength depends on physical properties of crystal and phase delays between transducers.

Acoustic-optic deflectors use electrical inputs to modify phase delay and power levels of acoustic waves in order to reach desired deflection angles. This adjustment enables the desired deflection angle to be achieved.

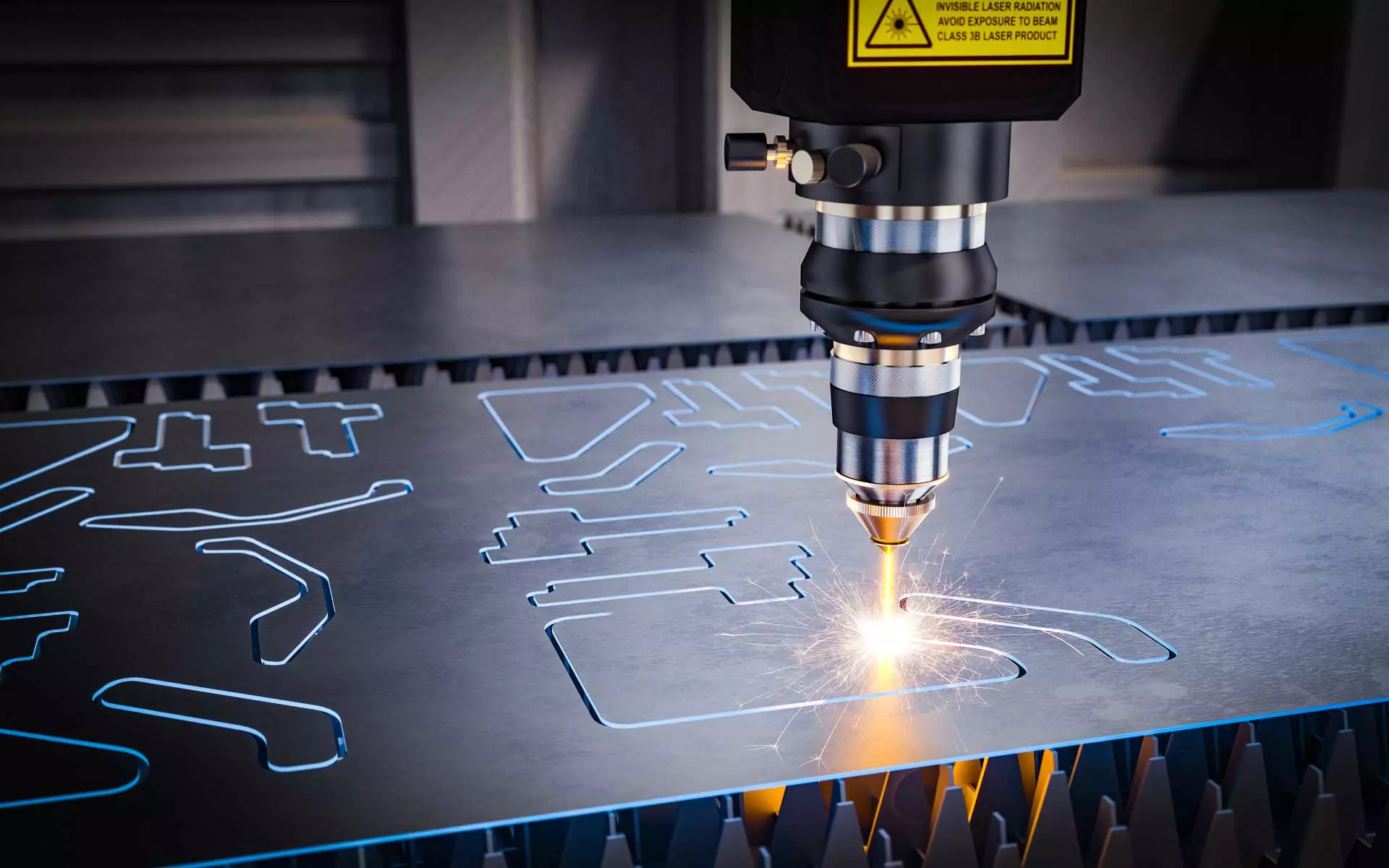

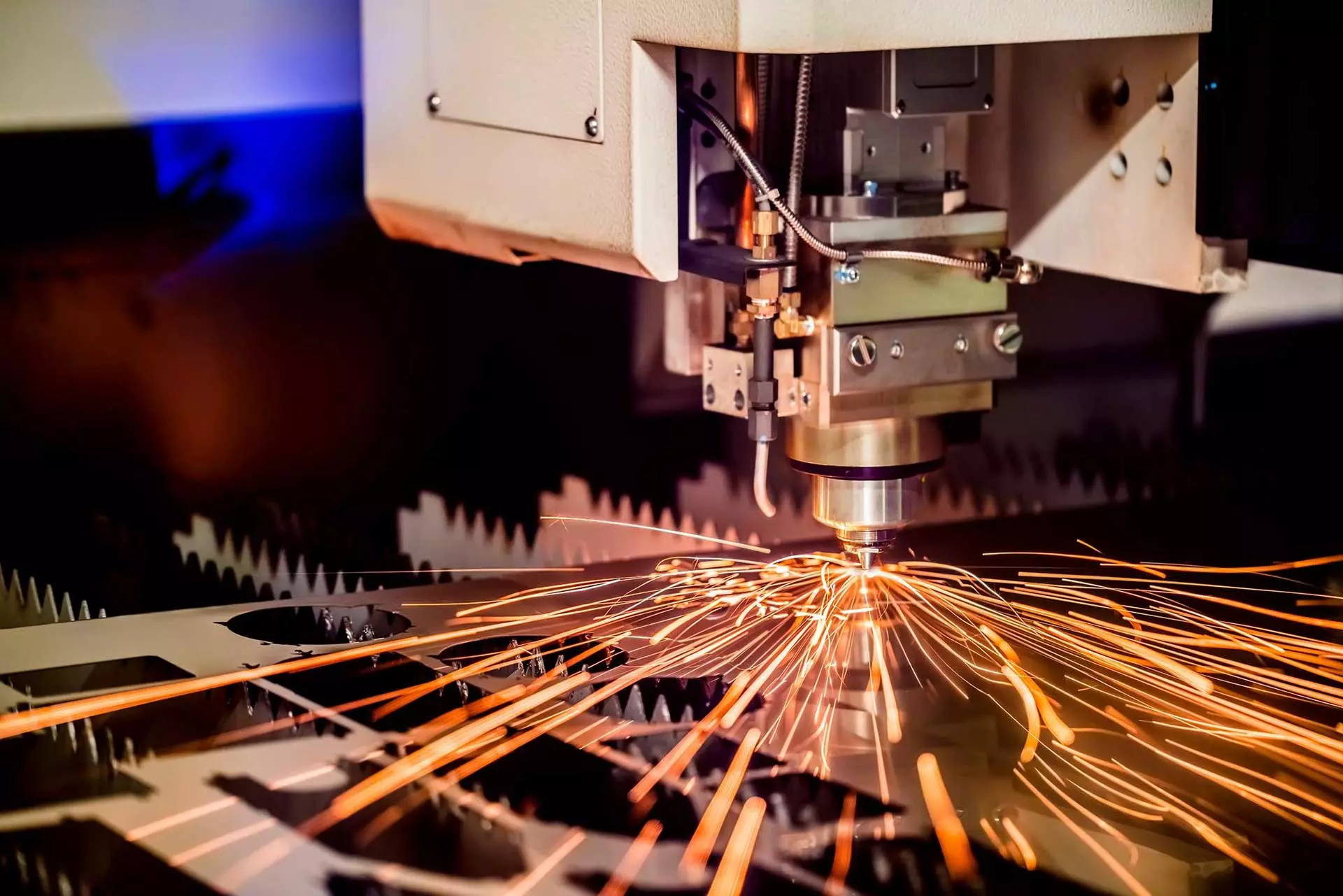

For example, when using laser beams for via drilling on substrates, an acousto-optic deflector may be adjusted to deflect it in order to reach specific positions. This deflection may be achieved by altering frequencies of acoustic waves which in turn alter their Bragg angle of diffraction and adjust deflection accordingly.

Acousto-optic deflectors have another use: steering laser beams without employing mechanical movement – something which is typically time-consuming or costly – via phase delay adjustments between neighboring acoustic transducers; these transducers may be located throughout a workpiece for optimal results in simultaneously redirecting its laser beam in various locations.

This compound has found widespread application in electronics applications, from CMOS and RF/V/A switches to LED components and sensing and imaging applications.

Additionally, silicon is often utilized as the material in tunable filters and acousto-optic deflectors, devices used to control laser beam amplitude. They may also be utilized during manufacturing of optical fibers, holograms, or photonic circuits.

Acousto-optic devices are projected to experience significant growth between 2016-2022. These devices offer reliable and economical laser light modulation solutions.

These devices are typically controlled with electrical inputs to transducers that emit acoustic waves. These waves travel through crystals to deflect laser beams; their wavelength depends on physical properties of crystal and phase delays between transducers.

Acoustic-optic deflectors use electrical inputs to modify phase delay and power levels of acoustic waves in order to reach desired deflection angles. This adjustment enables the desired deflection angle to be achieved.

For example, when using laser beams for via drilling on substrates, an acousto-optic deflector may be adjusted to deflect it in order to reach specific positions. This deflection may be achieved by altering frequencies of acoustic waves which in turn alter their Bragg angle of diffraction and adjust deflection accordingly.

Acousto-optic deflectors have another use: steering laser beams without employing mechanical movement – something which is typically time-consuming or costly – via phase delay adjustments between neighboring acoustic transducers; these transducers may be located throughout a workpiece for optimal results in simultaneously redirecting its laser beam in various locations.