What are the advantages of using Acoustic-Optic Q-switching (AOQS) in lasers?

By actively controlling its Q factor (loss), AOQS allows lasers to produce pulses of high intensity light at various frequencies.

As opposed to electro-optic modulators, acousto-optic Q-switches offer greater durability and lower insertion loss compared to their electro-optic counterparts. Furthermore, these Q-switches can handle very high peak power without losing stability compared to electro-optic modulators.

As opposed to electro-optic modulators, acousto-optic Q-switches offer greater durability and lower insertion loss compared to their electro-optic counterparts. Furthermore, these Q-switches can handle very high peak power without losing stability compared to electro-optic modulators.

1. Short Pulses

Lasers’ short pulses offer many advantages. These pulses can improve material performance while creating a better balance between laser energy and heat production. Furthermore, these pulses have very high peak power ratings.

Short pulses enable more of the laser energy to reach its target material, which increases processing capability and is especially helpful when processing materials with higher absorption wavelengths than those being processed.

Acousto-optic Q-switching harnesses the acoustic waves found within every optically transmissive material to switch a laser beam on or off. When compressed or deflected by these waves, they change its index of refraction, which in turn determines where its light beam bends.

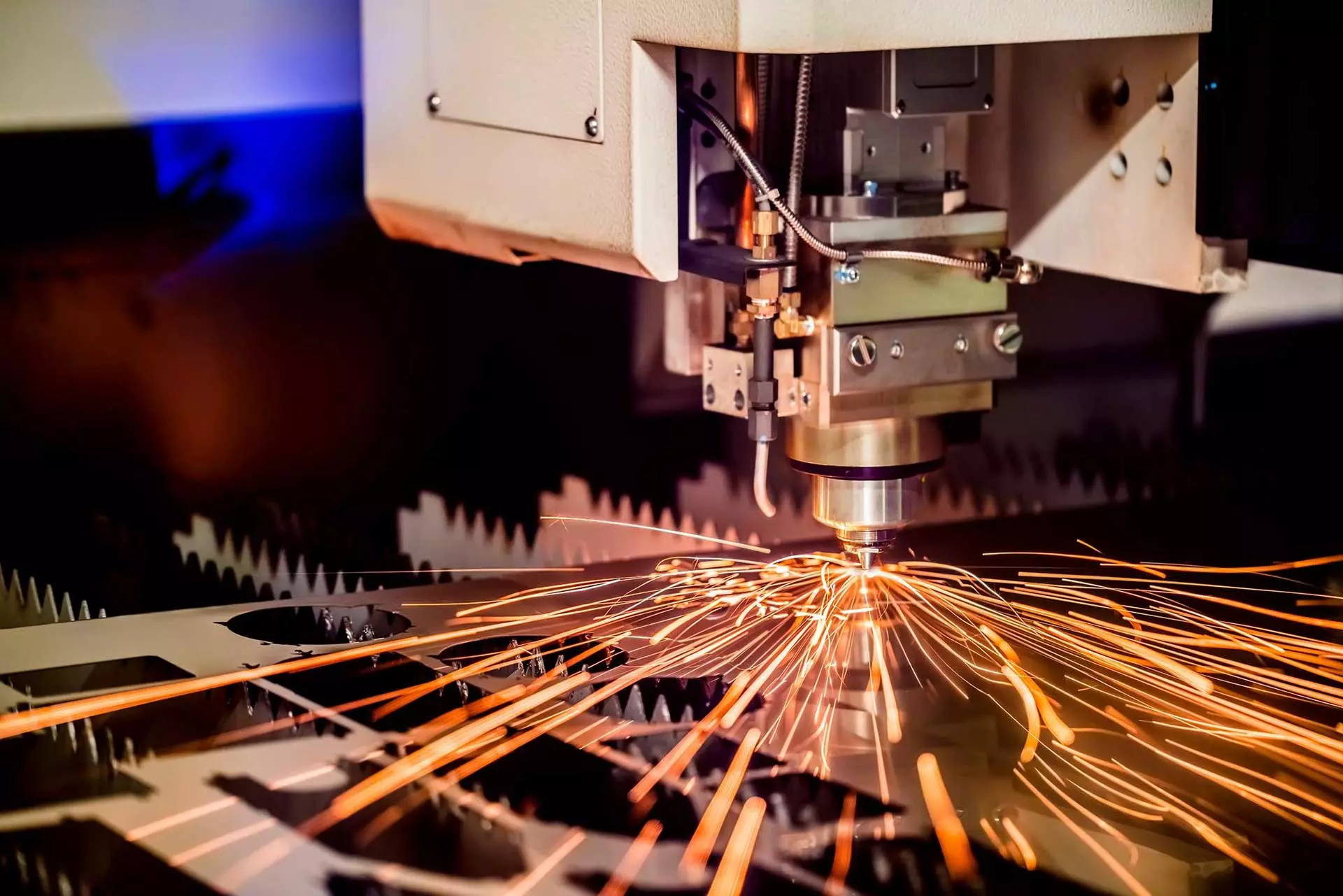

Combining the acoustic-optical effect with laser light can produce high peak power pulses for laser micromachining applications as well as other uses. Furthermore, this process creates extremely small timing jitter which is an invaluable aid when measuring material quality during cutting processes.

Acousto-optic Q-switching can also be used to switch on and off laser beams; to do this, the laser is pumped with RF sound waves.

Acoustic waves travel through the laser and change its index of refraction, altering its beam path and ultimately transitioning the laser from high loss state to low loss state.

Acousto-optic effect optimization may be further maximized for longer pulse durations; however, this requires long laser resonators which isn’t always practical in applications.

Short pulses enable more of the laser energy to reach its target material, which increases processing capability and is especially helpful when processing materials with higher absorption wavelengths than those being processed.

Acousto-optic Q-switching harnesses the acoustic waves found within every optically transmissive material to switch a laser beam on or off. When compressed or deflected by these waves, they change its index of refraction, which in turn determines where its light beam bends.

Combining the acoustic-optical effect with laser light can produce high peak power pulses for laser micromachining applications as well as other uses. Furthermore, this process creates extremely small timing jitter which is an invaluable aid when measuring material quality during cutting processes.

Acousto-optic Q-switching can also be used to switch on and off laser beams; to do this, the laser is pumped with RF sound waves.

Acoustic waves travel through the laser and change its index of refraction, altering its beam path and ultimately transitioning the laser from high loss state to low loss state.

Acousto-optic effect optimization may be further maximized for longer pulse durations; however, this requires long laser resonators which isn’t always practical in applications.

2. High Power

Acousto-optic Q-switching’s primary advantage lies in its ability to store and release energy rapidly in lasers. The process involves slowly pumping its gain medium for an extended period (approximately the lifetime of its excited energy state) before discharging all stored energy quickly to achieve high peak power levels.

Thus, lasers can serve as power sources to drive other equipment, such as kinematic arms for laser machining or spectrometers for laser-induced breakdown spectroscopy (LIBS). Furthermore, their high pulse energy generated with acousto-optic Q-switching allows them to perform numerous other tasks that demand highly intense, short pulses of light.

Actively Q-switched lasers may be more costly, but they also offer several other advantages over passively Q-switched devices, including:

Triggering – An actively Q-switched laser can be set to trigger at a specific time and pulse repetition rate, making synchronization with other instruments much simpler, such as kinematic laser arms or LIBS spectrometers.

Active q-switched lasers offer another major advantage over passive q-switches: their manufacturing is flexible. Passive q-switches require expensive drive electronics that make small packages difficult to construct.

Acoustic Q-switches, on the other hand, are very straightforward and simple to make; typically ranging in size from one millimeter to ten centimeters. Furthermore, acousto-optic transducers often connect directly with crystals through metal bonding rather than organic glues or epoxy systems, which makes them more resilient against thermal cycling while being more durable overall.

Thus, lasers can serve as power sources to drive other equipment, such as kinematic arms for laser machining or spectrometers for laser-induced breakdown spectroscopy (LIBS). Furthermore, their high pulse energy generated with acousto-optic Q-switching allows them to perform numerous other tasks that demand highly intense, short pulses of light.

Actively Q-switched lasers may be more costly, but they also offer several other advantages over passively Q-switched devices, including:

Triggering – An actively Q-switched laser can be set to trigger at a specific time and pulse repetition rate, making synchronization with other instruments much simpler, such as kinematic laser arms or LIBS spectrometers.

Active q-switched lasers offer another major advantage over passive q-switches: their manufacturing is flexible. Passive q-switches require expensive drive electronics that make small packages difficult to construct.

Acoustic Q-switches, on the other hand, are very straightforward and simple to make; typically ranging in size from one millimeter to ten centimeters. Furthermore, acousto-optic transducers often connect directly with crystals through metal bonding rather than organic glues or epoxy systems, which makes them more resilient against thermal cycling while being more durable overall.

3. High Stability

High stability lasers can be beneficial in numerous applications, particularly for long-term usage of your lasers in applications like atomic clocks or laser communications systems. High stability can make a big difference for applications like these.

Maintain high stability by adhering to several key rules. Keep your laser cool, utilize an effective temperature control system, and monitor its power output over time to ensure its stability.

Manufacturers typically recommend giving your laser time to warm up for 30 minutes prior to using it so it can reach thermal equilibrium and avoid power spikes, which can make an enormous difference in the power you receive from it! So be sure to abide by these recommendations!

An effective method to achieve high stability is by employing a carefully stabilized reference cavity, like a laser diode. Such devices allow users to identify whether their laser’s frequency has changed, as well as help correct any potential issues that might be occurring.

Electronic controllers can also help detect frequency deviations and apply corrective signals, with optimal performance being obtained when they have been tailored specifically to fit both lasers and frequency measurement devices.

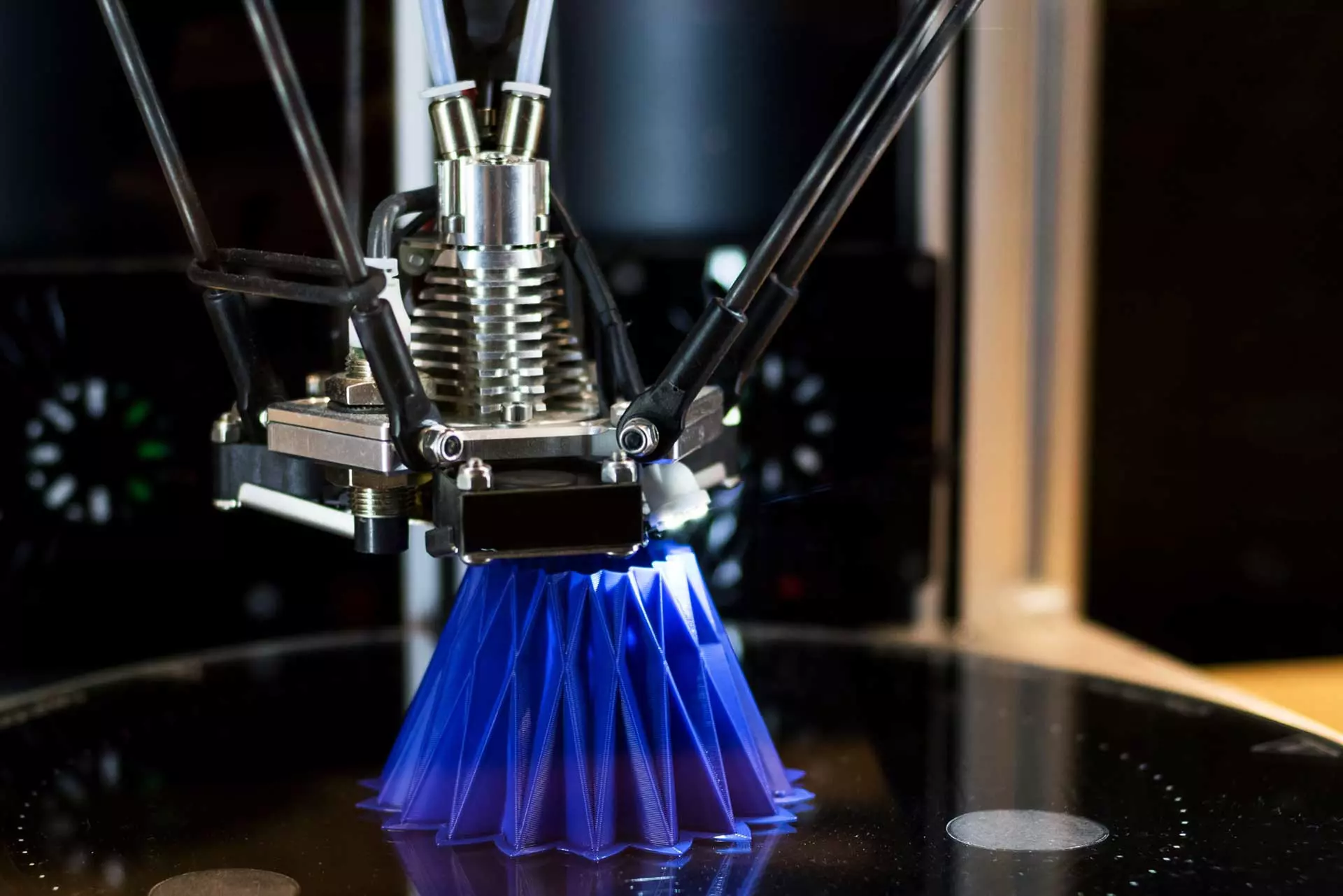

Recently, we developed a compact all-silicon laser head that is highly stable. Easy to store and move around, this new laser head combines the advantages of an optical cavity with a passively Q-switched Nd:YVO4 laser for high output power that is both stable and delivers it reliably – ideal for applications in various fields.

Maintain high stability by adhering to several key rules. Keep your laser cool, utilize an effective temperature control system, and monitor its power output over time to ensure its stability.

Manufacturers typically recommend giving your laser time to warm up for 30 minutes prior to using it so it can reach thermal equilibrium and avoid power spikes, which can make an enormous difference in the power you receive from it! So be sure to abide by these recommendations!

An effective method to achieve high stability is by employing a carefully stabilized reference cavity, like a laser diode. Such devices allow users to identify whether their laser’s frequency has changed, as well as help correct any potential issues that might be occurring.

Electronic controllers can also help detect frequency deviations and apply corrective signals, with optimal performance being obtained when they have been tailored specifically to fit both lasers and frequency measurement devices.

Recently, we developed a compact all-silicon laser head that is highly stable. Easy to store and move around, this new laser head combines the advantages of an optical cavity with a passively Q-switched Nd:YVO4 laser for high output power that is both stable and delivers it reliably – ideal for applications in various fields.

4. Low Loss

Active Q-switched lasers often produce much higher pulse energies compared to passively Q-switched ones, as the active switch can be timed so as to open at exactly the moment when metastable state decay causes full population inversion in the gain medium.

Acousto-optic Q-switching works by altering the refractive index of materials and thus altering how light bends through them – typically through shock waves being applied directly onto them.

This can be an excellent way to achieve low loss conditions without resorting to gain media that are susceptible to high absorption, especially when used with materials that have high refraction losses such as infrared emitters.

Ge AO crystal is typically employed to construct feedback optical cavities that achieve up to 80% deflection efficiency of laser beam propagating through cells at reasonable acoustic power levels.

Pumped RF power creates an acoustic wave which travels to a Ge AO crystal in the cell and deflects it away from one of the laser’s axisymmetric mirrors, altering its quality factor (Q) enough for it to stop lasing action altogether.

As a result, a Q-switch pulse appeared at 50 kHz PRF of the RF power with an approximate time delay (TD) of 3.2 microseconds due to both the time taken for an acoustic wave to travel along its path and for Q-switch to form from spontaneous emission noise.

Once an acoustic wave has reached the crystal, it turns off and RF power is turned back on again via switch S, meaning only short periods of transmitsive state will allow an AO cell to switch from low loss condition to high loss condition prior to reaching the end of a Q-switched pulse tail.

Acousto-optic Q-switching works by altering the refractive index of materials and thus altering how light bends through them – typically through shock waves being applied directly onto them.

This can be an excellent way to achieve low loss conditions without resorting to gain media that are susceptible to high absorption, especially when used with materials that have high refraction losses such as infrared emitters.

Ge AO crystal is typically employed to construct feedback optical cavities that achieve up to 80% deflection efficiency of laser beam propagating through cells at reasonable acoustic power levels.

Pumped RF power creates an acoustic wave which travels to a Ge AO crystal in the cell and deflects it away from one of the laser’s axisymmetric mirrors, altering its quality factor (Q) enough for it to stop lasing action altogether.

As a result, a Q-switch pulse appeared at 50 kHz PRF of the RF power with an approximate time delay (TD) of 3.2 microseconds due to both the time taken for an acoustic wave to travel along its path and for Q-switch to form from spontaneous emission noise.

Once an acoustic wave has reached the crystal, it turns off and RF power is turned back on again via switch S, meaning only short periods of transmitsive state will allow an AO cell to switch from low loss condition to high loss condition prior to reaching the end of a Q-switched pulse tail.

5. High Speed

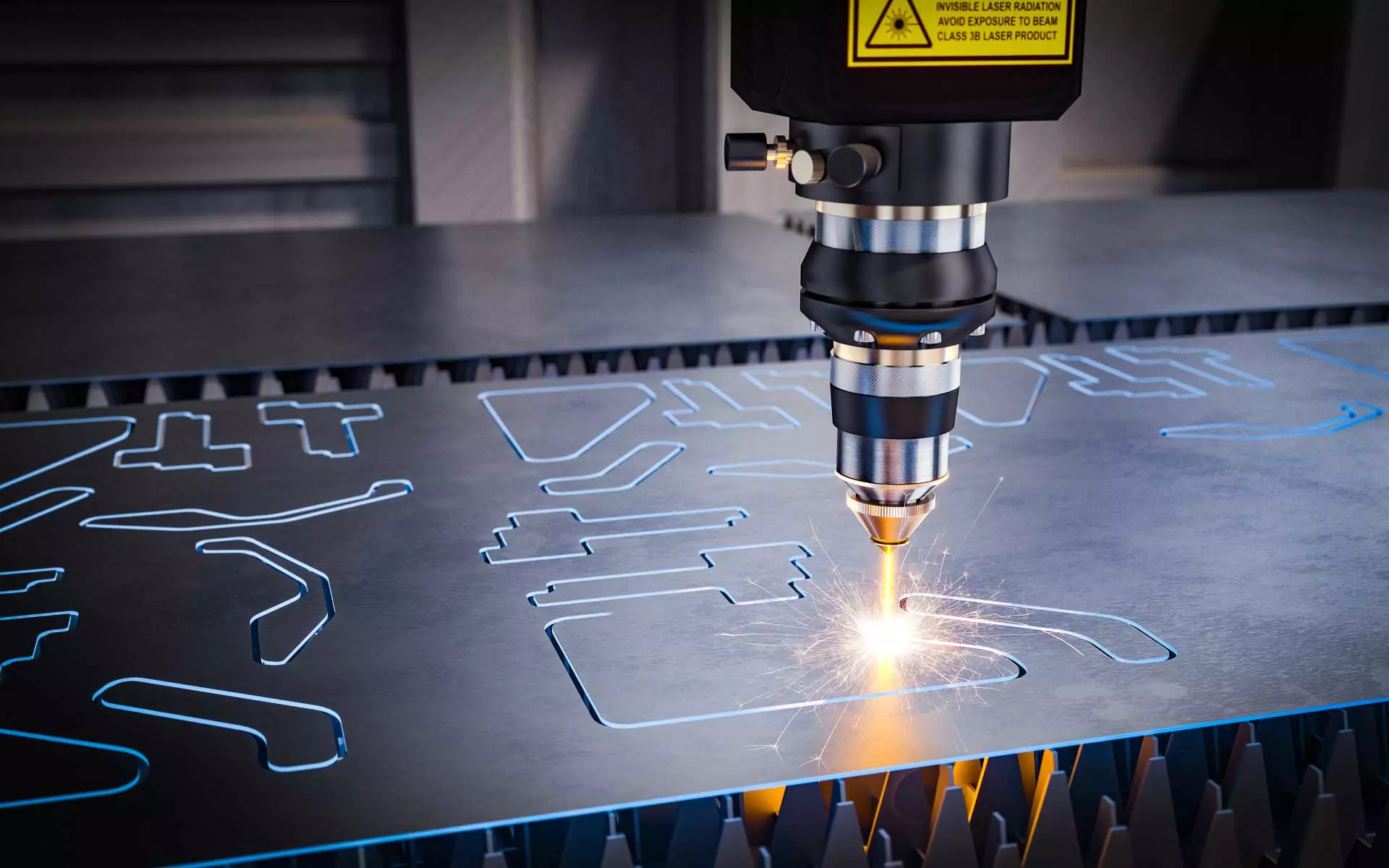

Q-switched lasers produce short, intense pulses which are well suited to various applications. For instance, they are effective at vaporizing thin layers of resistive materials without damaging their substrate underneath; additionally they can also be used for cutting, etching and machining metals.

Designing a laser system involves many considerations that may impact its outcome: PRF (pulse repetition frequency), gain medium and material composition are all vitally important in selecting an optimal type of laser for any given application.

High speed lasers that utilize acousto-optic Q-switching can operate at high repetition rates of 10kHz or more, providing smaller mode areas and significantly lowering energy per pulse and stored energy before each pulse. This results in reduced stored energy between pulses.

Due to this reason, many laser manufacturers are opting for acousto-optic Q-switching over electro-optic switching for Q-switching purposes. Acoustic cells offer numerous benefits including higher PRF and shorter wavelength, but have one significant drawback compared to electro-optic cells: their transit time from transducer to laser resonator is significantly longer.

Lasers operating in pulsed mode present unique challenges. Pulses must be short enough to avoid transit time delays without rolling off too quickly; otherwise they risk disrupting laser performance and leading to unexpected emissions.

Feedback between laser and workpiece may cause interference with Q-switching process and cause significant interference to Q-switching process, especially when dealing with reflective materials like copper and aluminum, or flat surfaces.

Designing a laser system involves many considerations that may impact its outcome: PRF (pulse repetition frequency), gain medium and material composition are all vitally important in selecting an optimal type of laser for any given application.

High speed lasers that utilize acousto-optic Q-switching can operate at high repetition rates of 10kHz or more, providing smaller mode areas and significantly lowering energy per pulse and stored energy before each pulse. This results in reduced stored energy between pulses.

Due to this reason, many laser manufacturers are opting for acousto-optic Q-switching over electro-optic switching for Q-switching purposes. Acoustic cells offer numerous benefits including higher PRF and shorter wavelength, but have one significant drawback compared to electro-optic cells: their transit time from transducer to laser resonator is significantly longer.

Lasers operating in pulsed mode present unique challenges. Pulses must be short enough to avoid transit time delays without rolling off too quickly; otherwise they risk disrupting laser performance and leading to unexpected emissions.

Feedback between laser and workpiece may cause interference with Q-switching process and cause significant interference to Q-switching process, especially when dealing with reflective materials like copper and aluminum, or flat surfaces.