An acousto-optic device works when sound waves interact with the refractive index of a medium and cause periodic variations to its index of refraction, altering how light passes through. This creates periodic variations that alter how it passes through and deflect light that passes through it.

Acousto-optic devices are commonly employed for applications including Q-switched lasers, ion traps, optical tweezers and spectrometers. These devices can deflect, modulate, frequency shift and rotate polarization of light beams for use in various purposes.

Acousto-optic devices are commonly employed for applications including Q-switched lasers, ion traps, optical tweezers and spectrometers. These devices can deflect, modulate, frequency shift and rotate polarization of light beams for use in various purposes.

Infrared

Infrared devices are increasingly utilized in medical settings for applications ranging from pain relief (via electrical stimulation of tissue) and identification of molecules using vibrational spectroscopy – this technique uses infrared light to analyze organic compounds’ chemical properties while simultaneously identifying individual molecules based on their vibrational frequencies.

Infrared wavelengths are longer than those of visible light, enabling infrared to penetrate materials more deeply and penetrate them more effectively into optical systems that need to be operated remotely, such as telescopes and spacecraft.

Therefore, infrared devices are frequently employed to transmit data over short distances. They use infrared (IR) light-emitting diodes to generate a concentrated beam of radiation that users aim at receivers that convert it to electrical current and interpret according to a coded message, enabling users to communicate with remote controls and PDAs that conform with standards published by IrDA, or Infrared Data Association.

Acousto-optic devices are used in laser equipment to modify the characteristics of materials through which light passes, altering its refractive index or band gap. They may also serve as light beam deflectors allowing users to control where a laser beam emerges from it.

As opposed to electro-optic devices, which combine analog and digital components, acousto-optic devices require materials with excellent acoustic and optical properties – most notably figure of merit and attenuation factor as selection parameters. A variety of materials exist; figure of merit being an essential consideration when making your selection decision.

Acoustic-optic devices can also be used to alter the properties of light in other ways, including deflecting it into different spatial modes, shifting its frequency or rotating its polarization. These effects are known as Brillouin scattering and are caused by periodic variations in material’s index of refraction.

Acoustic properties of acousto-optic materials may differ significantly depending on their material composition and the pressure exerted upon them, meaning acousto-optic products must be carefully selected to optimize performance in specific applications.

Infrared wavelengths are longer than those of visible light, enabling infrared to penetrate materials more deeply and penetrate them more effectively into optical systems that need to be operated remotely, such as telescopes and spacecraft.

Therefore, infrared devices are frequently employed to transmit data over short distances. They use infrared (IR) light-emitting diodes to generate a concentrated beam of radiation that users aim at receivers that convert it to electrical current and interpret according to a coded message, enabling users to communicate with remote controls and PDAs that conform with standards published by IrDA, or Infrared Data Association.

Acousto-optic devices are used in laser equipment to modify the characteristics of materials through which light passes, altering its refractive index or band gap. They may also serve as light beam deflectors allowing users to control where a laser beam emerges from it.

As opposed to electro-optic devices, which combine analog and digital components, acousto-optic devices require materials with excellent acoustic and optical properties – most notably figure of merit and attenuation factor as selection parameters. A variety of materials exist; figure of merit being an essential consideration when making your selection decision.

Acoustic-optic devices can also be used to alter the properties of light in other ways, including deflecting it into different spatial modes, shifting its frequency or rotating its polarization. These effects are known as Brillouin scattering and are caused by periodic variations in material’s index of refraction.

Acoustic properties of acousto-optic materials may differ significantly depending on their material composition and the pressure exerted upon them, meaning acousto-optic products must be carefully selected to optimize performance in specific applications.

Microwave

In the past, acousto-optic devices were utilized for an array of applications such as optical modulators, frequency shifters, switches, filters, isolators, spectrum analyzers, scanners, and correlators. With light-matter interactions increasing across many environments such as data centers and microwave photonics, controlling these interactions requires novel device designs in order to remain under control.

One potential solution involves combining bulk-wave acousto-optic devices with subwavelength photonic crystal nanocavities, creating efficient and wideband acousto-optic devices suitable for photonic integrated circuit (PIC) technology applications.

One such innovation is the creation of microchip-scale acousto-optic devices using bulk-wave acoustic waves in suspended lithium niobate thin films to form microchip-scale acousto-optic devices, capable of reaching high frequencies and modulation efficiency despite having lower overall efficiency compared with their bulk counterparts.

This phenomenon can be explained by the short interaction lengths between light and acoustic waves in these integrated devices, with such deflectors having only 3.5% deflection efficiency compared with 90%+ in bulk deflectors.

Acoustic-optic devices are widely employed in radar systems. From low-bandwidth ground stations to satellites that transmit communications at higher wavelengths, acousto-optic devices have numerous applications within radar systems – not to mention aircraft and military vehicles.

Most global data, television, and telephone communications are sent using microwave transmission over long distances between ground stations and satellites. Microwaves can easily be focused into narrow beams that don’t spread easily in air; this facilitates point-to-point communications.

One major part of global communications falls within the extremely high frequency (EHF) radio wave range between 3 and 30 GHz, providing wide bandwidth and fast data transfer rates. Transmission beyond this point becomes limited to several kilometers due to atmospheric absorption of microwaves.

Microwave electronics development is driven primarily by consumer demand for high-performance communication and radar equipment. However, this highly fragmented market features several companies like Analog Devices Inc., Teledyne Technologies Incorporated, Thales Group and L3Harris Technologies, Inc. which specialize in producing small scale low cost microwave devices suitable for space, commercial and defense industries; investing heavily in R&D as well as acquiring other businesses to bolster their product offering portfolio.

One potential solution involves combining bulk-wave acousto-optic devices with subwavelength photonic crystal nanocavities, creating efficient and wideband acousto-optic devices suitable for photonic integrated circuit (PIC) technology applications.

One such innovation is the creation of microchip-scale acousto-optic devices using bulk-wave acoustic waves in suspended lithium niobate thin films to form microchip-scale acousto-optic devices, capable of reaching high frequencies and modulation efficiency despite having lower overall efficiency compared with their bulk counterparts.

This phenomenon can be explained by the short interaction lengths between light and acoustic waves in these integrated devices, with such deflectors having only 3.5% deflection efficiency compared with 90%+ in bulk deflectors.

Acoustic-optic devices are widely employed in radar systems. From low-bandwidth ground stations to satellites that transmit communications at higher wavelengths, acousto-optic devices have numerous applications within radar systems – not to mention aircraft and military vehicles.

Most global data, television, and telephone communications are sent using microwave transmission over long distances between ground stations and satellites. Microwaves can easily be focused into narrow beams that don’t spread easily in air; this facilitates point-to-point communications.

One major part of global communications falls within the extremely high frequency (EHF) radio wave range between 3 and 30 GHz, providing wide bandwidth and fast data transfer rates. Transmission beyond this point becomes limited to several kilometers due to atmospheric absorption of microwaves.

Microwave electronics development is driven primarily by consumer demand for high-performance communication and radar equipment. However, this highly fragmented market features several companies like Analog Devices Inc., Teledyne Technologies Incorporated, Thales Group and L3Harris Technologies, Inc. which specialize in producing small scale low cost microwave devices suitable for space, commercial and defense industries; investing heavily in R&D as well as acquiring other businesses to bolster their product offering portfolio.

Longitudinal

Acoustic-optic devices are increasingly utilized for applications spanning telecommunications, security and sensing. Their advantages over conventional acoustic waves include operating in various temperature and pressure conditions as well as having higher sensitivities.

Acoustic-optic sensors can be constructed out of many materials. Most often, these include crystalline quartz and fused silica; other common options are chalcogenide glasses (often known as Flint Glasses), indium phosphide, and germanium, often found in infrared devices.

Acoustic devices can also be constructed from piezoelectric materials like boron nitride and aluminum nitride, which possess piezoelectric properties to generate mechanical waves when an electric field is applied to them, propagating across surfaces while producing acoustic energy that can be measured.

Most devices function as acoustic wave sensors, meaning that they can detect output of acoustic waves by measuring attenuation and frequency shifts. These detectors tend to be small, inexpensive and highly sensitive – making them highly effective solutions.

Long-term measurements with these instruments can be challenging due to measurement errors that accumulate over the duration of an experiment, but various solutions have been devised to overcome such challenges.

One approach involves setting up the device at different times and then comparing results at each point to determine the optimal configuration for any given condition. This practice, known as longitudinal data analysis, is widely employed by telecom and medical companies alike.

One method involves moving a device along a specific path while measuring its acoustic power output. For instance, in an ultrasound scanner device is moved along this path while acoustic pulses are being generated and its output compared against its counterpart pulse for changes in sound output.

Some devices detect liquids using other modes of propagation than just acoustic waves, including TSM and SH-APM devices, which utilize horizontal shear waves that don’t interfere with liquid, thus permitting operation without excessive damping. Conversely, SAW sensors emit an extremely significant surface-normal displacement that produces compression waves within liquid.

Acoustic-optic sensors can be constructed out of many materials. Most often, these include crystalline quartz and fused silica; other common options are chalcogenide glasses (often known as Flint Glasses), indium phosphide, and germanium, often found in infrared devices.

Acoustic devices can also be constructed from piezoelectric materials like boron nitride and aluminum nitride, which possess piezoelectric properties to generate mechanical waves when an electric field is applied to them, propagating across surfaces while producing acoustic energy that can be measured.

Most devices function as acoustic wave sensors, meaning that they can detect output of acoustic waves by measuring attenuation and frequency shifts. These detectors tend to be small, inexpensive and highly sensitive – making them highly effective solutions.

Long-term measurements with these instruments can be challenging due to measurement errors that accumulate over the duration of an experiment, but various solutions have been devised to overcome such challenges.

One approach involves setting up the device at different times and then comparing results at each point to determine the optimal configuration for any given condition. This practice, known as longitudinal data analysis, is widely employed by telecom and medical companies alike.

One method involves moving a device along a specific path while measuring its acoustic power output. For instance, in an ultrasound scanner device is moved along this path while acoustic pulses are being generated and its output compared against its counterpart pulse for changes in sound output.

Some devices detect liquids using other modes of propagation than just acoustic waves, including TSM and SH-APM devices, which utilize horizontal shear waves that don’t interfere with liquid, thus permitting operation without excessive damping. Conversely, SAW sensors emit an extremely significant surface-normal displacement that produces compression waves within liquid.

Shear

Acousto-optic devices are increasingly being utilized across both industrial and telecom verticals. They are commonly employed to deflect laser beams and modulate them by altering their amplitude, phase and frequency of light waves based on an interaction between sound waves and light waves in different crystals.

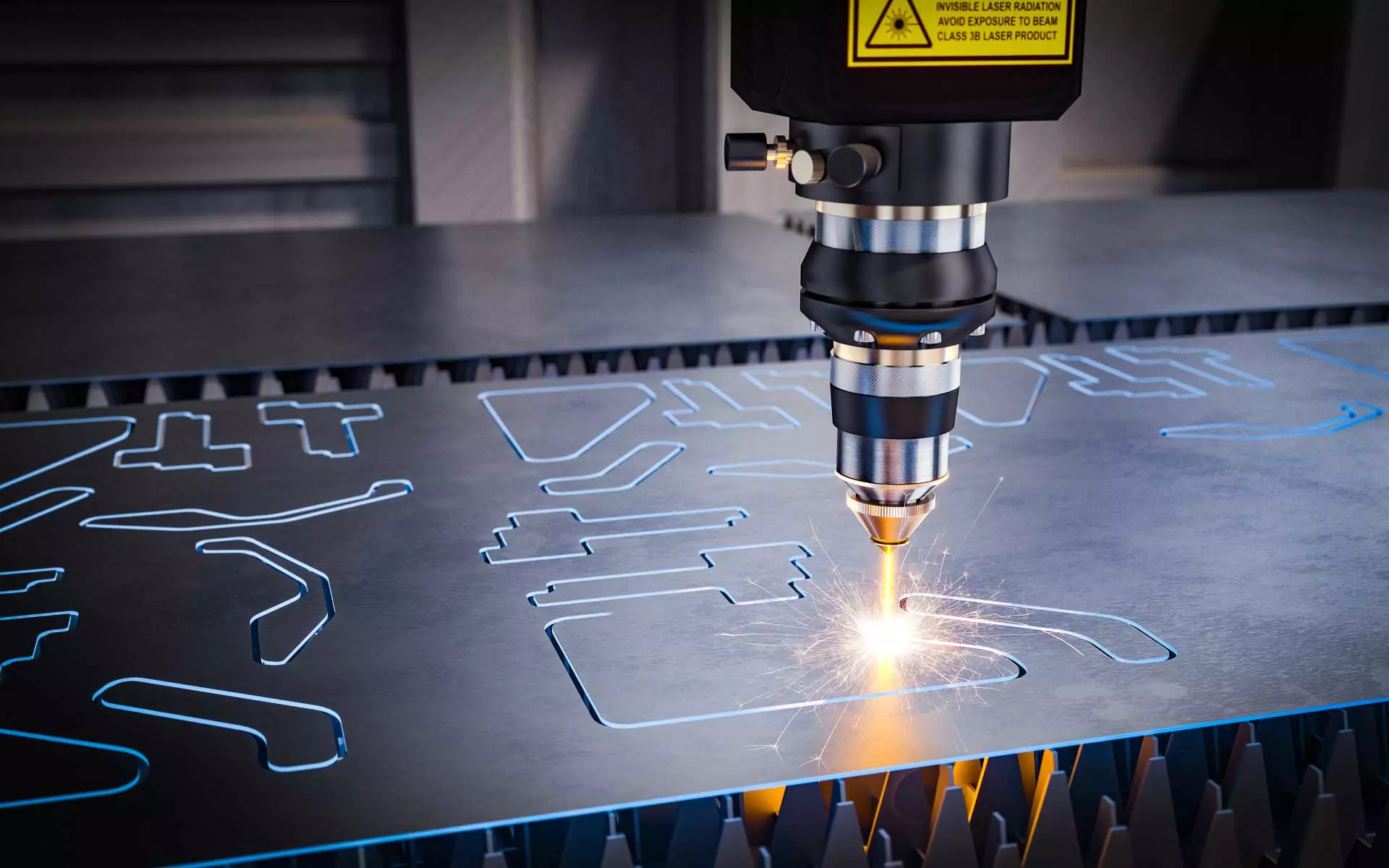

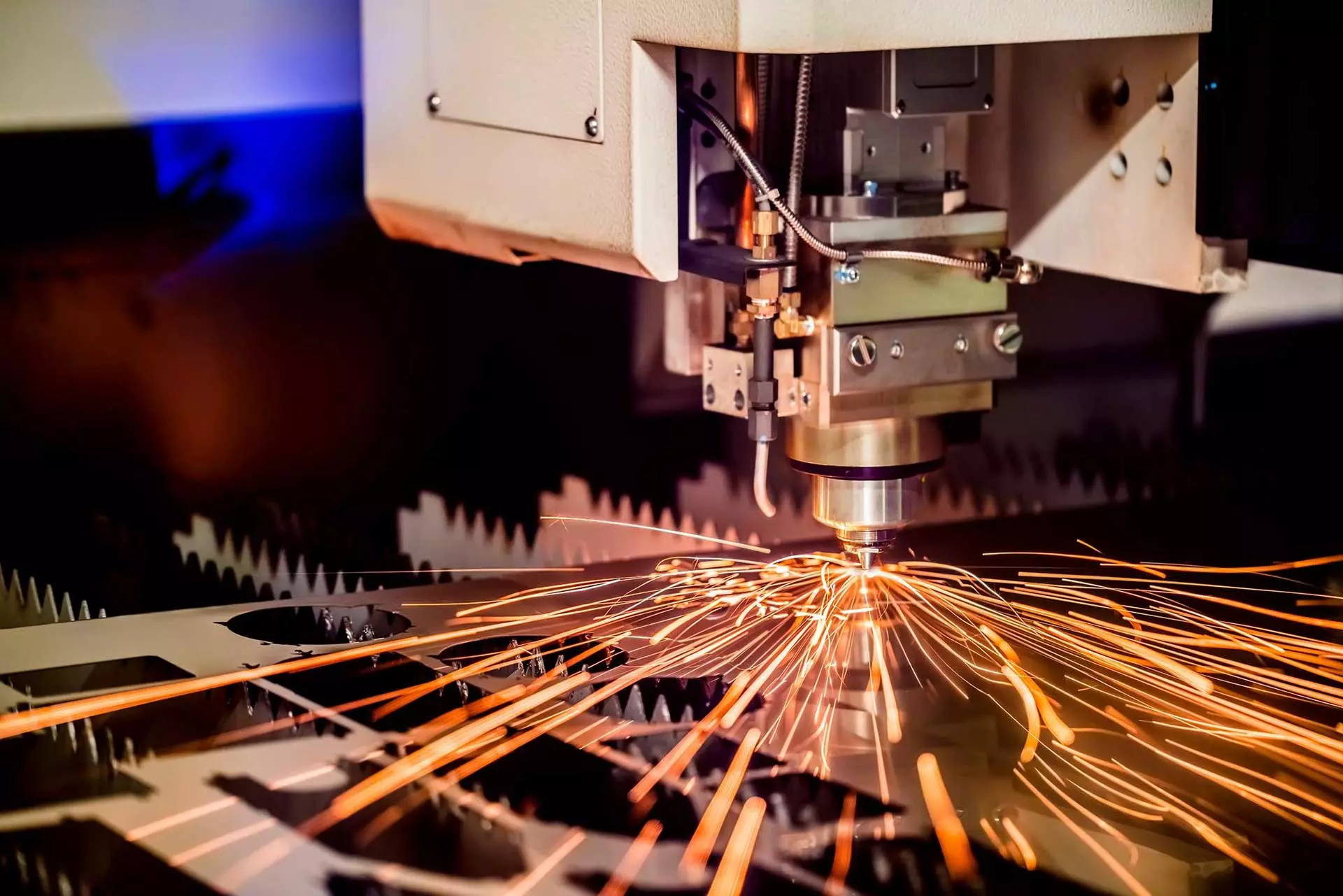

Acousto-optic devices are widely utilized in the semiconductor and electronics industries for Q-switching and mode locking of laser beams, as well as used by automotive industries for marking, cutting, etching and deflashing purposes. Their utilization is expected to grow due to their many benefits for use within this vertical.

Oil and gas industries are among the largest users of acousto-optic devices, boasting huge revenues and operating expenses, respectively. Their market for these devices has experienced moderate growth between 2016-2022.

APAC region acousto-optic devices market is projected to experience the highest compound annual compound annual compound growth during its forecast period, driven by increasing population base and investments in research and development activities in this industry. Laser technology usage will likely also spur significant expansion.

Similar to the growth in acousto-optic devices industry, laser technology continues to see exponential increase in life science and research verticals such as Q-switching and mode locking applications, as well as expected increases in Q-switching/mode locking demand. Acousto-optic market expansion in life science/research vertical is expected.

Additionally, the market for acousto-optic devices within semiconductor and electronics vertical is expected to experience compound annual compound annual compound annual compound growth of 7.244% between 2016-2022. Half-cut technology (which combines mechanical saws with laser cutters to cut material) should help boost this segment as well.

Furthermore, the acousto-optics industry is expected to experience growth thanks to increasing demand for its devices in the oil and gas sector – particularly those used for sensing and measuring applications within this vertical.

Acousto-optic devices are widely utilized in the semiconductor and electronics industries for Q-switching and mode locking of laser beams, as well as used by automotive industries for marking, cutting, etching and deflashing purposes. Their utilization is expected to grow due to their many benefits for use within this vertical.

Oil and gas industries are among the largest users of acousto-optic devices, boasting huge revenues and operating expenses, respectively. Their market for these devices has experienced moderate growth between 2016-2022.

APAC region acousto-optic devices market is projected to experience the highest compound annual compound annual compound growth during its forecast period, driven by increasing population base and investments in research and development activities in this industry. Laser technology usage will likely also spur significant expansion.

Similar to the growth in acousto-optic devices industry, laser technology continues to see exponential increase in life science and research verticals such as Q-switching and mode locking applications, as well as expected increases in Q-switching/mode locking demand. Acousto-optic market expansion in life science/research vertical is expected.

Additionally, the market for acousto-optic devices within semiconductor and electronics vertical is expected to experience compound annual compound annual compound annual compound growth of 7.244% between 2016-2022. Half-cut technology (which combines mechanical saws with laser cutters to cut material) should help boost this segment as well.

Furthermore, the acousto-optics industry is expected to experience growth thanks to increasing demand for its devices in the oil and gas sector – particularly those used for sensing and measuring applications within this vertical.